MIL-PRF-19500/395K

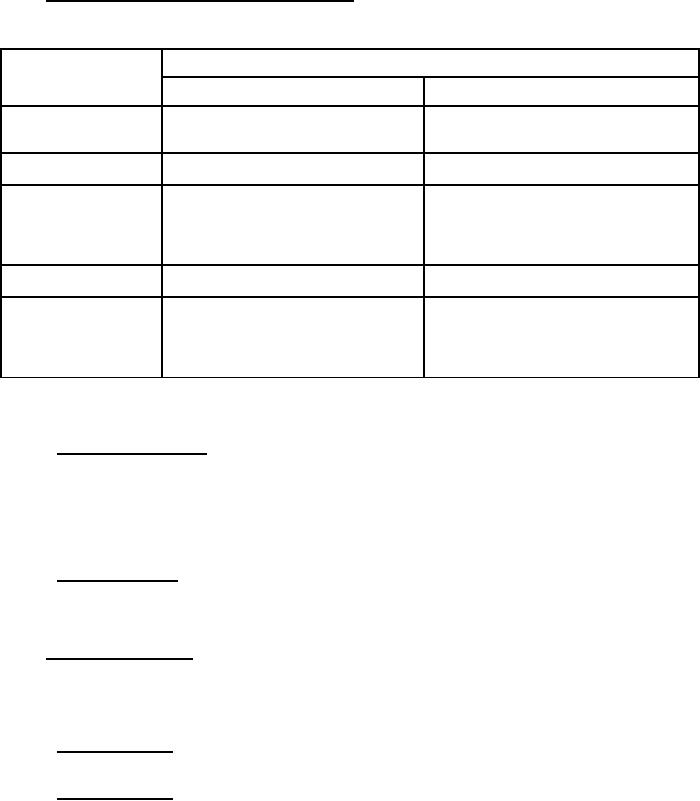

4.3 Screening (JANTX, JANTXV and JANS levels only). Screening shall be in accordance with table E-IV of

MIL-PRF-19500, and as specified herein. The following measurements shall be made in accordance with table I

herein. Devices that exceed the limits of table I herein shall not be acceptable.

Screen (see table E-IV

Measurement

of MIL-PRF-19500)

JANS level

JANTX and JANTXV levels

(1) 3c

Thermal impedance, method 3131 of

Thermal impedance, method 3131 of

MIL-STD-750 (see 4.3.2).

MIL-STD-750 (see 4.3.2).

9

ICBO2 and hFE3.

Not applicable.

11

ICBO2; hFE3;

ICBO2 and hFE3.

ĆICBO2 = 100 percent or 25 nA dc,

whichever is greater;

ĆhFE3 = ±15 percent of initial value.

12

See 4.3.1.

See 4.3.1.

13

Subgroups 2 and 3 of table I herein;

Subgroup 2 of table I herein;

ĆICBO2 = 100 percent or 25 nA dc,

ICBO2 = 100 percent or 25 nA dc,

whichever is greater;

whichever is greater;

ĆhFE3 = ±15 percent of initial value.

ĆhFE3 = ±15 percent of initial value.

(1) Shall be performed anytime after temperature cycling, screen 3a; and does not need to be repeated in

screening requirements.

4.3.1 Power burn-in conditions. Power burn-in conditions are as follows: VCB = 10 - 30 V dc. Power shall be

applied to achieve TJ = +135°C minimum using a minimum PD = 75 percent of PT maximum, TA ambient rated as

defined in 1.3. NOTE: No heat sink or forced air cooling on the devices shall be permitted. With approval of the

qualifying activity and preparing activity, alternate burn-in criteria (hours, bias conditions, TJ, and mounting conditions)

may be used for JANTX and JANTXV quality levels. A justification demonstrating equivalence is required. In

addition, the manufacturing site's burn-in data and performance history will be essential criteria for burn-in

modification approval.

4.3.2 Thermal impedance. The thermal impedance measurements shall be performed in accordance with

method 3131 of MIL-STD-750 using the guidelines in that method for determining IM, IH, tH, tSW (and VH where

appropriate). The thermal impedance limit used in screen 3c and table I, subgroup 2 shall be set statistically by the

supplier. See table IV, group E, subgroup 4 herein.

4.4 Conformance inspection. Conformance inspection shall be in accordance with MIL-PRF-19500, and as

specified herein. If alternate screening is being performed in accordance with MIL-PRF-19500, a sample of screened

devices shall be submitted to and pass the requirements of subgroups 1 and 2 of table I herein, inspection only

(table E-VIB of MIL-PRF-19500, group B, subgroup 1 is not required to be performed since solderability and resistance

to solvents testing is performed in table I herein).

4.4.1 Group A inspection. Group A inspection shall be conducted in accordance with MIL-PRF-19500, and table I

herein.

4.4.2 Group B inspection. Group B inspection shall be conducted in accordance with the tests and conditions

specified for subgroup testing in table E-VIA (JANS) of MIL-PRF-19500 and table E-VIB (small die flow, JAN, JANTX,

and JANTXV). Electrical measurements (end-points) and delta requirements shall be in accordance with table I,

subgroup 2 and table II herein; delta requirements only apply to subgroups B4 and B5. See table E-VIC of

MIL-PRF-19500 and 4.4.2.2 for JAN, JANTX, and JANTXV group B testing. Electrical measurements (end-points)

and delta requirements for JAN, JANTX, and JANTXV shall be after each step in 4.4.2.2 and shall be in accordance

with table I, subgroup 2 and table II herein.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business