MIL-PRF-19500/467A

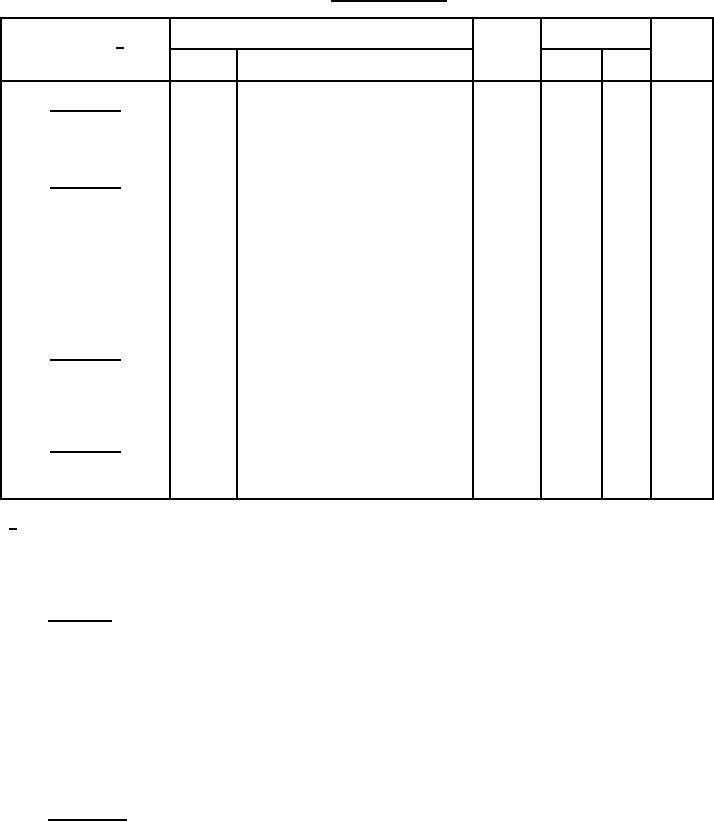

TABLE I. Group A inspection.

Unit

MIL-STD-750

Limits

Symbol

Inspection 1/

Min

Max

Method

Conditions

Subgroup 1

2071

Visual and mechanical

inspection

Subgroup 2

Θ = 0 degrees (see 4.5.1)

mcd

3.0

0.5

IV1

Luminous intensity

IF = 20 mA dc

Θ = 30 degrees; IF = 20 mA dc

Luminous intensity

IV2

0.3

mcd

μA dc

Reverse current

4016

DC method; VR = 3 V dc

IR

1.0

Forward voltage

4011

DC method, IF = 20 mA dc

VF

2.0

V dc

Subgroup 3

TA = +100°C

High temperature:

Θ = 0 degrees, IF = 20 mA dc

Luminous intensity

IV1

0.45

3.0

mcd

Subgroup 4

4001

VR = 0; f = 1 MHz

C

300

pF

Capacitance

1/ For sampling plan, see MIL-PRF-19500.

5. PACKAGING

* 5.1 Packaging. For acquisition purposes, the packaging requirements shall be as specified in the contract or

order (see 6.2). When packaging of materiel is to be performed by DoD or in-house contractor personnel, these

personnel need to contact the responsible packaging activity to ascertain packaging requirements. Packaging

requirements are maintained by the Inventory Control Point's packaging activities within the Military Service or

Defense Agency, or within the Military Service's system commands. Packaging data retrieval is available from the

managing Military Department's or Defense Agency's automated packaging files, CD-ROM products, or by

contacting the responsible packaging activity.

6. NOTES

* (This section contains information of a general or explanatory nature that may be helpful, but is not mandatory.

The notes specified in MIL-PRF-19500 are applicable to this specification.)

* 6.1 Intended use. Semiconductors conforming to this specification are intended for original equipment design

applications and logistic support of existing equipment.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business