MIL-PRF-19500P

APPENDIX E

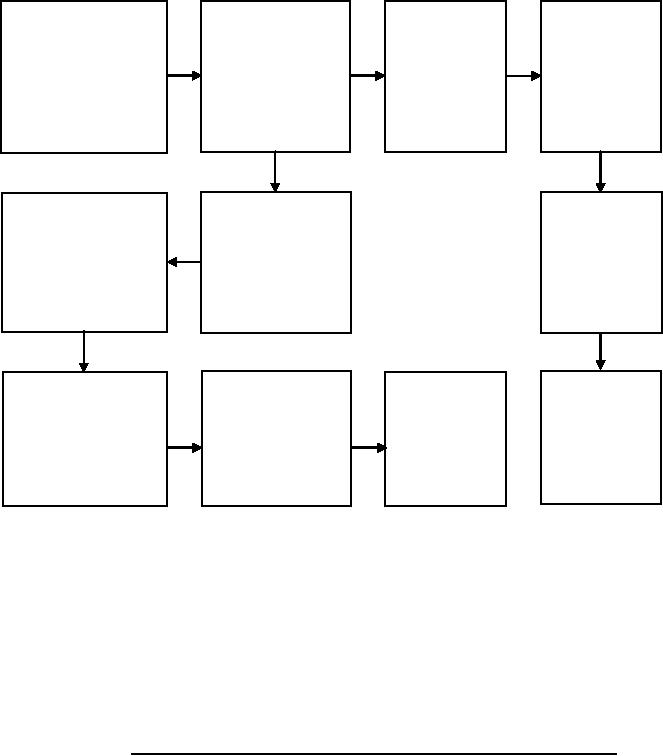

PRODUCTION PROCESS

1. RAW MATERIAL

CONFORMANCE

REVIEW OF

2. FACTORY PROCESS

INSPECTION LOTS

INSPECTION

GROUPS

3. INTERNAL VISUAL AS

FORMED AFTER

TESTING ON

A, B, AND C

SPECIFIED IN THE

FINAL ASSEMBLY

INSPECTION

SPECIFICATION

LOT TO VERIFY

DATA FOR

OPERATION

SHEET

THE SAMPLE

ACCEPT OR

PLAN OF

REJECT

GROUPS A, B,

SEE NOTE 1

AND C

DEVICES PROPOSED

FOR JANTX/TXV

JAN

ALL SPECIFIED TABLE

ASSURANCE TYPES

E-IV 100-PERCENT

STOCKING

SHALL MAINTAIN

SCREENS FOR JANTX,

ORIGINAL LOT

JANTXV AS APPLICABLE

IDENTITY AND DATE

CODE

SEE NOTES 2 AND 3

SCREENING

VERIFICATION TESTS

REVIEW OF GROUPS

JAN

JANTX OR

A, B, C, AND D (AS

PREPARATION

JANTXV

GROUP A, SUBGROUP 1

APPLICABLE)

FOR DELIVERY

PREPARATION

AND 2

FOR DELIVERY

GROUP B, SUBGROUP 1

FOR LOT ACCEPT OR

AND GROUP D

REJECT

SEE NOTES 4, 5, AND 6

NOTES:

1. All product proposed for JANTXV processing shall have been subjected to and passed JANTXV internal

visual 100-percent screening in accordance with table E-IV herein at this step (except for clear glass

JANTXV diodes which shall be subjected to internal visual prior to body paint or mark).

2. If a JAN inspection lot is not processed in parallel with the material designated for JANTX and JANTXV,

all groups A, B, C, and D testing shall be performed on a JANTX or JANTXV inspection lot as shown on

figure E-1.

3. The order of all screening tests shall be performed as specified in table E-IV.

4. Method 2026 of MIL-STD-750, omit steam ageing, sample size is 15 leads c = 0. This modified B1 testing

cannot be used as a solderability inspection date.

5. Method 1022 of MIL-STD-750, sample size is 15 devices c = 0.

6. If the inspection lot is composed of a collection of sublots, each sublot shall pass full group A inspection

as specified.

FIGURE E-2. Alternate order of procedure diagram for JAN, JANTX, and JANTXV device types.

91

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business