MIL-PRF-19500P

APPENDIX E

E.6 CONFORMANCE INSPECTION

E.6.1 Conformance inspection. Conformance Inspection shall be conducted in accordance with the requirements

of groups A, B, and C for the specified quality level as well as group D to the applicable RHA level. If a lot is

withdrawn in a state of failing to meet conformance requirements and is not resubmitted, it shall be considered a

failed lot and reported as such. Each lot shall be subjected to groups A and B inspection. Successful completion of

group C conformance for a given quality level shall satisfy the group C requirements for all quality levels and devices

represented by the structurally identical group. The grouping of structurally identical devices (see E.3.2) shall be as

agreed between the manufacturer and the qualifying activity. JANS devices shall not be used to represent the other

quality levels. If a manufacturer elects to eliminate all or any conformance inspection steps substituting either a

process monitor or statistical process control (SPC) procedures (when approved by the preparing activity and

qualifying activity), the manufacturer is only relieved of the responsibility of performing the conformance inspection

(see 4.4). The manufacturer still bears full liability for any failure that may result if these tests are performed at a later

time. A manufacturers reliability program may be used in lieu of all or any conformance inspection when equivalent

to or compliant with C.8.3.

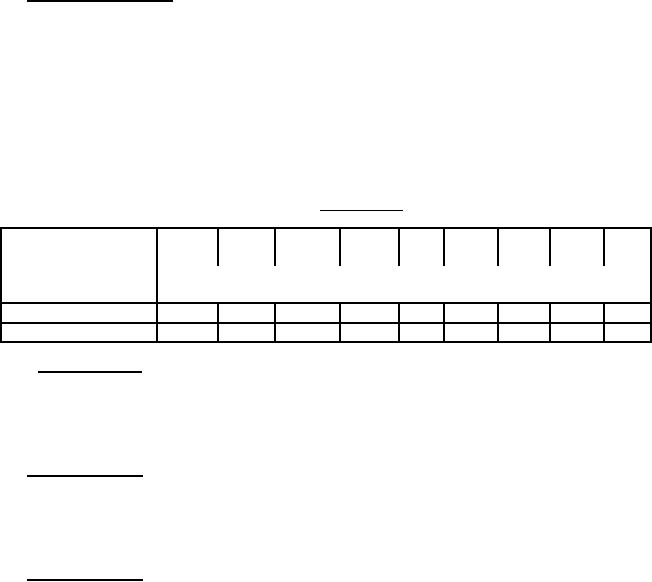

TABLE E-I. Sample plans.

Maximum percent

50

30

20

15

10

7

5

3

2

defective or lambda,

accept number (c)

Minimum sample sizes (for device-hours required for life test, multiply by 1,000).

(r = c + 1)

0

5

8

11

15

22

32

45

76

116

1

8

13

18

25

38

55

77

129

195

E.6.1.1 Nonconformance. Lots which fail subgroup requirements of groups A, B, C, or D may be resubmitted in

accordance with the provisions of E.3.6. However, if the lot is not resubmitted or fails resubmission, the lot shall not

be shipped and the JAN marking shall be obliterated or removed within 30 days. For additional guidance on group D

failures see E.6.5. Manufacturers shall notify the qualifying activity when a conformance inspection lot is removed

from consideration as a JAN branded inspection lot. All catastrophic failures (opens, shorts) shall be evaluated. The

manufacturer's procedure(s) shall define when a formal failure analysis is required to be performed.

E.6.2 Group A inspection. Group A inspection shall be performed on each inspection lot and shall consist of visual

and mechanical inspection and electrical tests as specified in table E-V and the specification sheet. Group A

inspection may be performed in any order. If an inspection lot is made up of a collection of sublots, each sublot shall

pass group A inspection as specified. Unless the entire inspection lot has seen the same screening, devices which

have received PIND (one pass condition A ) may not be considered as candidates for this inspection. This does not

apply to devices PIND tested as a process monitor.

E.6.3 Group B inspection. Group B inspection shall be performed on each inspection lot except for the

specification sheets that specify the flow in table E-VIC. Group B shall be in accordance with table E-VIA, E-VIB, or

E-VIC as applicable, and the specification sheet. Testing of one device type sublot in any subgroup or step shall be

considered as complying with the requirements for that subgroup or step for all types in the lot. Different device types

may be used for each subgroup except for JANS. All inspections, except for life tests, shall be applied only to

completed and fully marked devices from lots which have been subjected to and passed the group A, subgroup 1, 2,

and 3 requirements. When the final lead finish is solder, or any plating prone to oxidation at high temperature, the

samples for life tests (table E-VIB, subgroups 3 and 6, and table E-VIA, subgroups 4 and 5) may be pulled prior to the

application of final lead finish. The test samples may be cleaned prior to the electrical end-point testing. An

evaluation shall be performed on all failures to determine if the failure mode is the result of a latent (time dependent)

defect, workmanship, or design weakness. Appropriate corrective action shall be performed as a result of the

evaluation. All tests within a subgroup shall be performed in the order specified except table E-VIA, subgroup 2, and

table E-VIB, subgroup 1.

94

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business