MIL-PRF-19500P

APPENDIX E

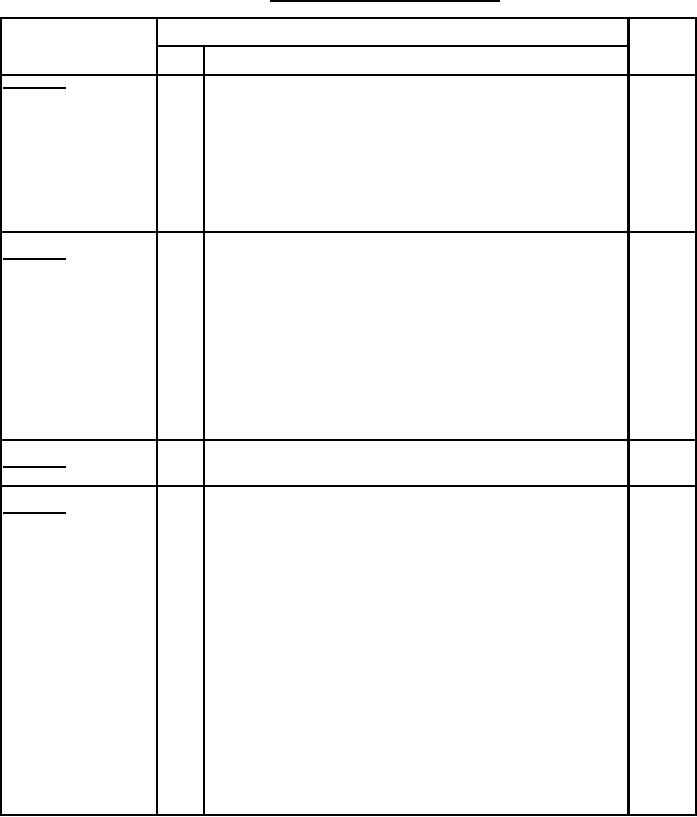

TABLE E-IX. Group E inspections (all quality levels).

Inspections

MIL-STD-750

Sample

plan

Method

Condition

Subgroup 1

45 devices,

c = 0 or as

Thermal shock or

1056

100 cycles or as specified.

specified.

Temperature cycling

1051

500 cycles minimum or as specified. Test condition C or max storage temp,

which ever is less.

Hermetic seal

1071

As applicable.

a. Fine leak

b. Gross leak

Electrical measurements

Group A, subgroup 2.

Subgroup 2

45 devices,

c = 0 or as

specified.

1037

As specified.

Intermittent operating life

Group A, subgroup 2.

Electrical measurements

or

Life test

1042

Condition A, B, C, or D.

Electrical measurements

Group A, subgroup 2.

or

Steady-state operating life

1026

As specified.

Electrical measurements

Group A, subgroup 2.

or

Blocking life

1048

As specified.

Electrical measurements

Group A, subgroup 2.

Subgroup 3

Not applicable

Subgroup 4

Thermal impedance curves N/A

Each supplier shall submit a thermal impedance (ZθJX) histogram of the entire N/A

(as applicable)

qualification lot. The histogram data shall be taken prior to the removal of

devices that are atypical for thermal impedance. Thermal impedance curves

(from ZθJX test pulse time to RθJX minimum steady-state time) of the best

device in the qual lot and the worst device in the qual lot (that meets the

supplier proposed screening limit), or from the thermal grouping, shall be

submitted. The optimal test conditions and proposed initial thermal impedance

screening limit shall be provided in the qualification report. Data indicating how

the optimal test conditions were derived for ZθJX shall also be submitted. The

proposed specification maximum thermal impedance curve shall be submitted.

The qualifying activity may approve a different ZθJX limit not to exceed the

specification's thermal curve for conformance inspection end-point

measurements as applicable. The supplier shall support (with applicable data)

their ZθJX end-point limit proposal when it exceeds the screening ZθJX limit. A

delta (read and record) ZθJX shall be determined by the manufacturer and

approved by the qualifying activity for all case mounted devices for

conformance inspection (intermittent life test and temperature cycling) end-

point measurements. Any exceptions shall be justified to, and approved by,

the qualifying activity. Equivalent data, procedures, or SPC plans may be used

for part, or all, of the above requirements.

See footnotes at end of table.

119

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business