MIL-PRF-19500P

APPENDIX H

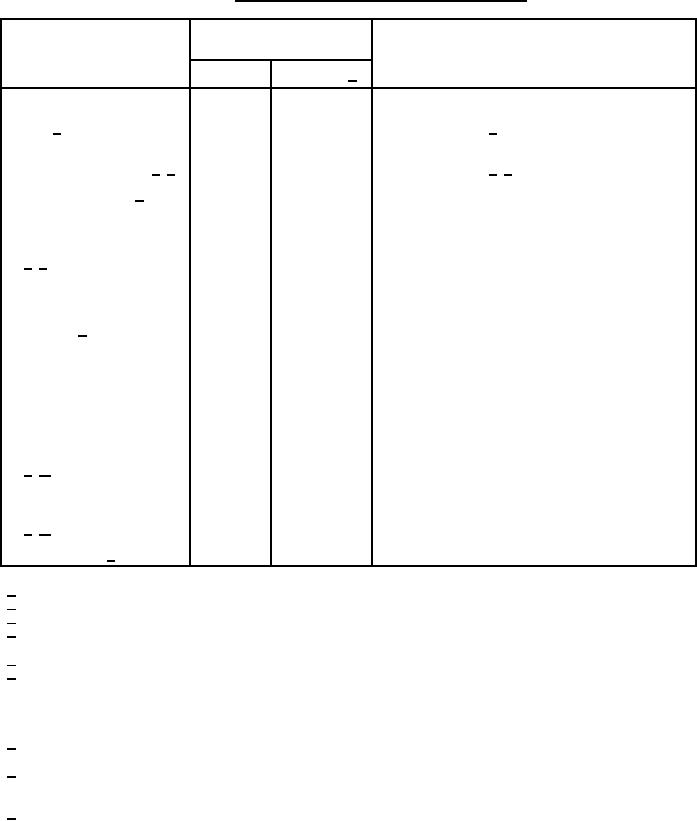

TABLE H-I. Coating thickness and composition requirements.

Thickness

Coating

microinch/micrometer

Coating composition requirements

Minimum

Maximum 1/

Hot solder dip (for round

60/1.52

NS

The solder bath shall have a nominal composition

leads) 2/

of Sn60 or Sn63. 3/

Hot solder dip (for all shapes

200/5.08

NS

The solder bath shall have a nominal composition

other than round leads) 2/ 4/

of Sn60 or Sn63. 3/ 5/

Tin plate (as plated) 6/

300/7.62

NS

Shall contain no more than 0.12 percent by weight

co-deposited organic material measured as

elemental carbon. See H.4.3. f.

Tin-lead plate (as plated)

200/5.08

NS

Shall consist of 3 to 50 percent by weight lead

4/ 6/

(balance nominally tin) homogeneously co-

deposited. Shall contain no more than 0.12

percent by weight co-deposited organic material

measured as elemental carbon.

Tin dipping 4/

100/2.54

See H.4.3.f.

Gold plate

10/.254

225/5.72

Shall contain a minimum of 99.7 percent gold.

Only cobalt shall be used as the hardener.

Silver plate

100/2.54

425/10.8

99.7 percent silver minimum.

Silver cladding

250

Nickel plate (electroplate)

50/1.27

350/8.89

The introduction of organic addition agents to

7/ 8/

nickel bath is prohibited. Up to 40 percent by

weight cobalt is permitted as a co-deposit.

Nickel plate (electroless)

50/1.27

250/6.35

The introduction of organic addition agents to

7/ 8/

nickel bath is prohibited.

Nickel cladding 9/

50/1.27

350/8.89

1/

NS = not specified.

2/

See H.4.3.a and H.4.3.b.

The solder Sn concentration in the pot may range from 50 percent Sn to 70 percent Sn.

3

4/

For threaded stud packages and for terminals not intended for mounting the device only, the minimum coating

thickness shall be 100 microinches/2.54 micrometers.

5/

As measured to the center of the flat.

6/

The maximum carbon content (and minimum lead content in tin-lead plate) shall be determined by the

manufacturer on at least a quarterly basis. The determination of carbon and lead content may be made by any

accepted analytical technique (e.g., for carbon: Pyrolysis, infrared detection (using an IR212, IR244 infrared

detector or equivalent); for lead: X-ray fluorescence, as long as the assay reflects the actual content in the total

deposited finish.

7/

The maximum specified thickness applies to the final coating, provided all previously deposited

nickel layers have been annealed to eliminate the residual deposition stress.

8/

Combinations of pre-plate electroplate or electroless nickel and final electroplate nickel finishing shall

not exceed 700 microinches/17.78 micrometers total. Combinations of pre-plate electroplate nickel

and final electroless nickel plate finishing shall not exceed 600 microinches total.

9/

Maximum nickel thickness applies only to lead material.

136

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business