MILPRF19500/114H

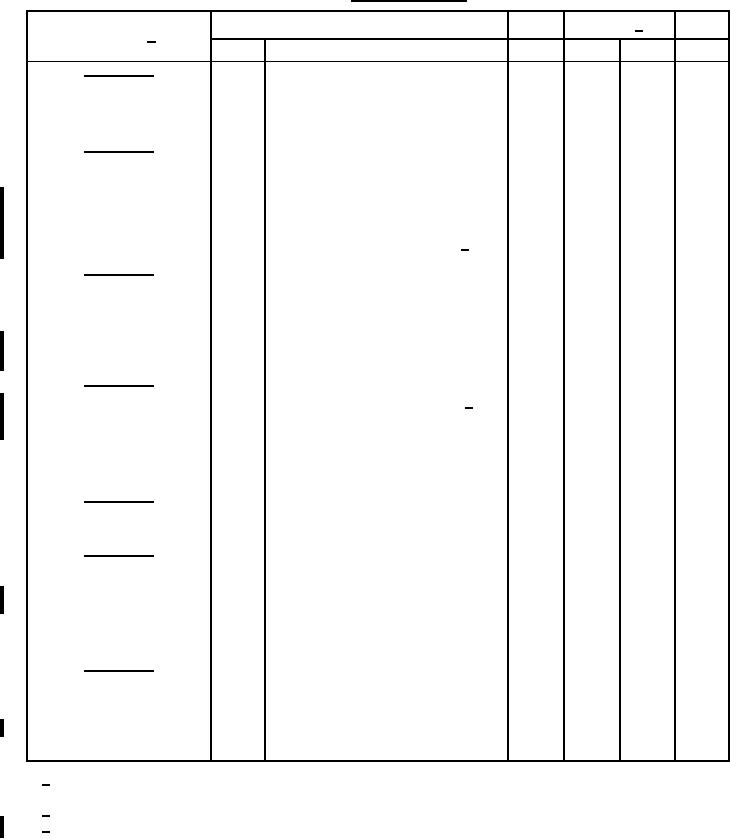

TABLE I. Group A inspection.

Symbol

Limits 2/

Unit

Inspection 1/

Method

Conditions

Min

Max

Subgroup 1

Visual and mechanical

2071

Inspection

Subgroup 2

V dc

Forward voltage

4011

1.5

IF = 10 A dc

VF

µA dc

Reverse current

4016

Col 11

VR = column 10 of table III;

IR1

DC method (see 4.5.7)

V dc

Regulator voltage

4022

Col 2

Col 3

IZ = column 4 of table III herein 3/

VZ

Subgroup 3

TA = 150°C

High temperature

operation:

µA dc

Reverse current

4016

Col 13

VR = column 10 of table III herein;

IR2

DC method

Subgroup 4

ohms

Small-signal breakdown

4051

Z

Col 5

IZ = column 4 of table III herein; 3/

impedance

Isig = 10 percent of IZ

ohms

Knee impedance

4051

Col 6

IZK = 5 mA dc;

ZK

Isig = 10 percent of IZ

Subgroup 5

Not applicable

Subgroup 6

Surge current (see 4.5.1)

4066

JANS level only

IZSM = column 9 of table III herein

End point electrical

See table I, subgroup 2 herein

measurements

Subgroup 7

V dc

Voltage regulation

JANS level only n = 22, c = 0

Col 8

VZ(reg)

(see 4.5.2)

%/°C

αVZ

4071

Col 12

Temperature coefficient of

IZ = column 4 of table III herein;

regulator voltage (see 4.5.4)

T1 = 30 ±3°C, T2 = T1 +100°C

1/

For JANS, all devices required by the specified sampling plan shall be subjected to subgroups 2, 3, and 4

combined.

Column references are for table III herein.

2/

During this test, the TC of the diode shall be equal to 30 ±3°C.

3/

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business