MIL-PRF-19500/144R

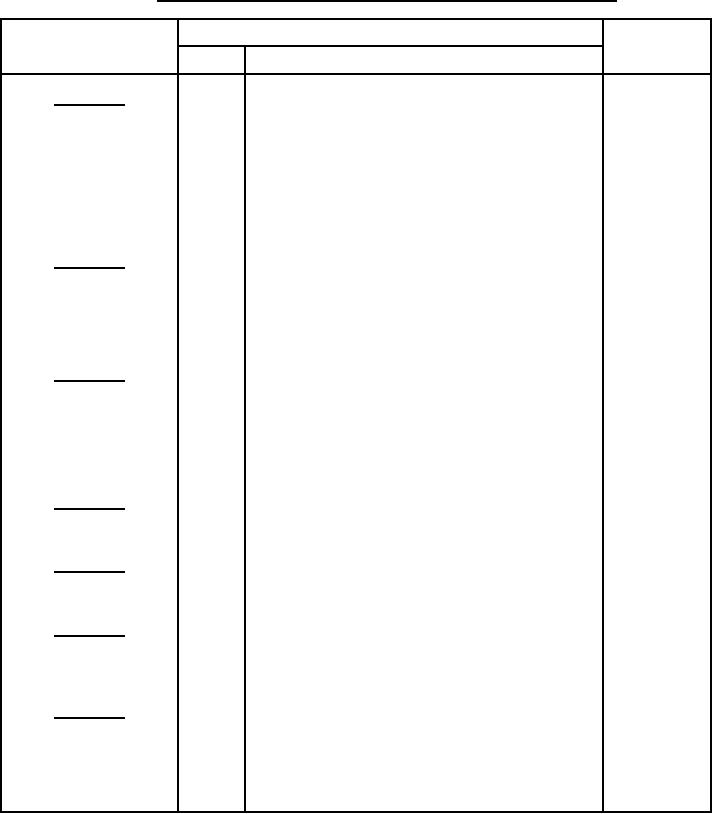

* TABLE II. Group E inspection (all quality levels) for qualification and requalification only.

Qualification

Inspection

inspection

Method

Conditions

Subgroup 1

n = 45, c = 0

100 cycles 0°C to 100°C.

Thermal shock (glass

1056

strain)

500 cycles, -65°C to +175°C.

Temperature cycling

1051

Hermetic seal

1071

Gross leak only. Fine and gross leak required for UB.

Electrical measurement

See table I, subgroup 2.

Subgroup 2

n = 45, c = 0

Intermittent operating life

1037

10,000 cycles; If = 300 mA dc, ton = toff = 1 minute.

*

See table I, subgroup 2.

Electrical measurements

Subgroup 4

Thermal resistance

3131

n = 15, c = 0

RθJSP can be calculated but shall be measured once in

the same package with a similar die size to confirm

calculations (may apply to multiple specification sheets).

Thermal impedance

See MIL-PRF-19500.

Sample size

curves

N/A

Subgroup 5

Not applicable

Subgroup 6

ESD

1020

Subgroup 8

Resistance to glass

1057

Test condition B. Test until failure occurs or to a

n = 45

cracking

maximum of 25 cycles, whichever comes first.

n = 22, c = 0

Subgroup 9

Monitored mission

1055

Not required for UB suffix devices.

temperature cycling

Electrical measurements

See table I, subgroup 2.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business