MILPRF19500/502G

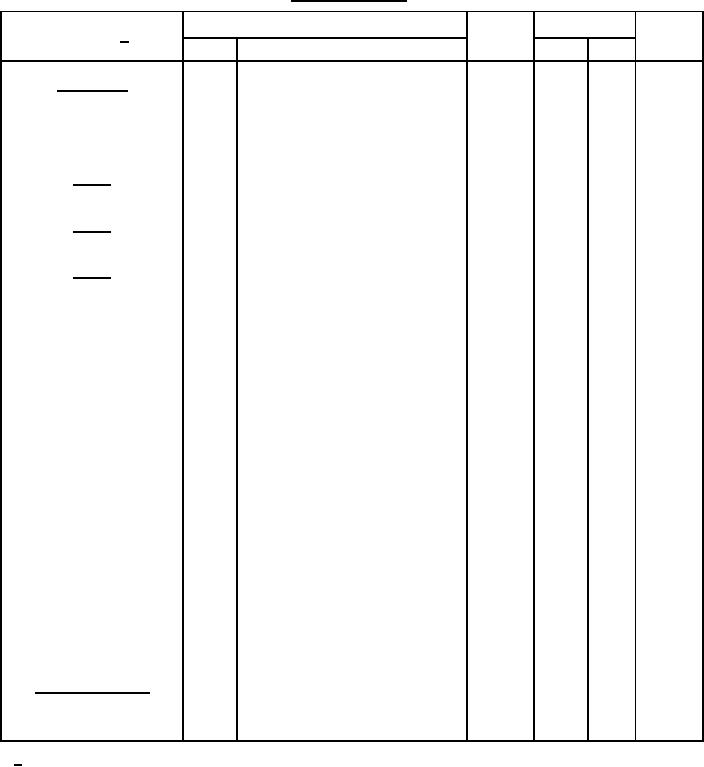

* TABLE I. Group A inspection Continued.

Limit

Inspection 1/

Symbol

Unit

Method

Conditions

Min

Max

Subgroup 5

TC = +25°C +10°C, 0°;

Safe operating area

3051

t ≥ 1 s; 1 cycle; (see figure 3)

(continuous dc)

Test 1

(Both device types)

VCE = 12.5 V dc; IC = 12 A dc

Test 2

(Both device types)

Fdvi8VCE = 30 V dc; IC = 5 A dc

Test 3

(2N6058)

VCE = 70 V dc; IC = 200 mA dc

(2N6059)

VCE = 90 V dc; IC = 155 mA dc

Safe operating area

3053

Load condition B;

(switching)

(clamped inductive load);

TA = +25°C; tr + tf ≤ 1.0 µs;

duty cycle ≤ 2 percent;

tp = 1 ms; (vary to obtain IC);

Rs = 0.10 Ω; RBB1 = 80 Ω;

VBB1 = 16 V dc; RBB2 = 100 Ω;

VBB2 = 1.5 V dc; IC = 12 A dc;

VCC = 20 V dc; RL ≤ 2 Ω;

L = 10 mH (Stancor C-2688 or

equivalent); (see figure 4).

2N6058

Clamp voltage = 80 +0, 5 V dc

2N6059

Clamp voltage = 100 +0, 5 V dc

Device fails if clamp voltage

not reached.

End-point electrical

See subgroup 2 of table I herein.

measurements

Subgroups 6 and 7

Not applicable

1/

For sampling plan, see MILPRF19500.

2/

This test required for the following end-point measurements only:

Group B, subgroups 2 and 3 (JAN, JANTX, and JANTXV).

Group C, subgroup 2 and 6.

Group E, subgroup 1.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business