MIL-PRF-19500/552G

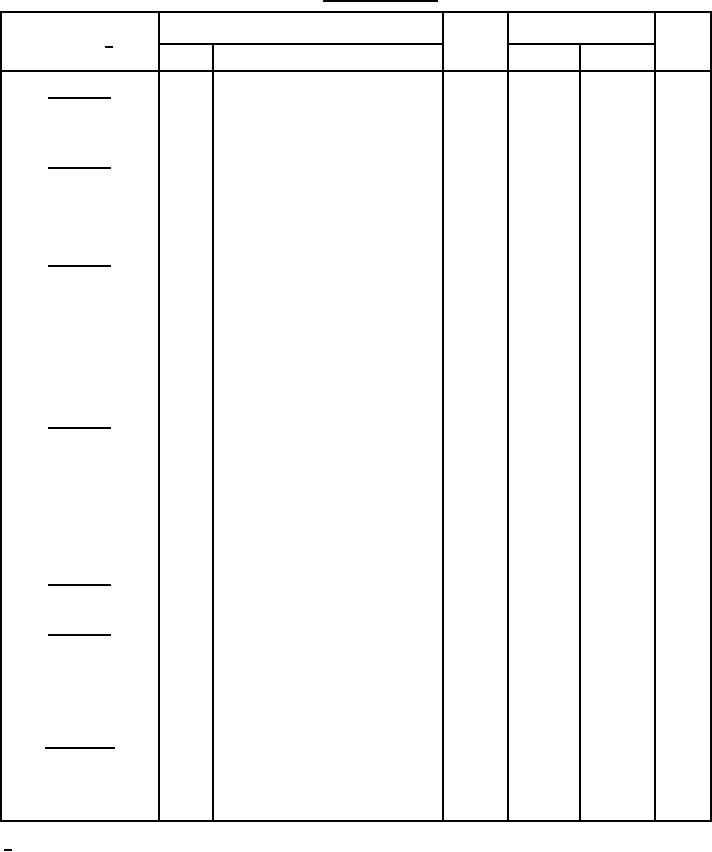

TABLE I. Group A inspection.

Limit

Inspection 1/

Symbol

Unit

Method

Conditions

Min

Max

Subgroup 1

Visual and mechanical

2071

Examination

Subgroup 2

tp ≤ 300 ms, duty cycle ≤ 2 percent; IBR

Breakdown voltage

4022

VBR1

Column 2 of

V dc

table II

= column 3 of table II

µA dc

DC method, VR = VRWM

Reverse current

4016

ID

Column 5 of

table II

(column 4 of table II)

Subgroup 3

tp ≤ 300 ms, duty cycle ≤ 2 percent; IBR

Minimum breakdown

4022

VBR2

Column 9 of

V dc

Voltage

table II

= column 3 of table II;

TA = -55°C

TA = 125°C

High temperature

operation:

µA dc

Reverse current leakage

4016

DC method, VR = VRWM,

ID2

Column 11

of table II

column 4 of table II

Subgroup 4

Clamping voltage

tp = 1.0 ms (see 4.5.2.a)

VC

Column 6 of

V(pk)

maximum (see 4.5.3)

table II

IPP = column 7 of table II

Forward voltage

4011

IF = 4 A dc

VF

1.5

V(pk)

IFM = 100 A (pk), tp = 300 µs,

Forward voltage

4011

VFM

4.8

V(pk)

duty cycle = 4 pulses per minute

maximum

Subgroup 5

Not applicable

Subgroup 6

One pulse, half sine wave 8.3 ms;

Surge current

4066

IFSM

IF = 0, IFSM = 130 A (pk),

VRWM = 0, TA = +25°C

Electrical measurements

Table III, steps 1 and 2

Subgroup 7

Forward clamping

tp = 1.0 ms (see 4.5.2.a) at IPP

VCF

Column

V(pk)

voltage (see 4.5.3)

10 of

except use forward direction

table II

current without prior bias voltage

1/ For sampling plan, see MIL-PRF-19500.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business