MIL-PRF-19500/312E

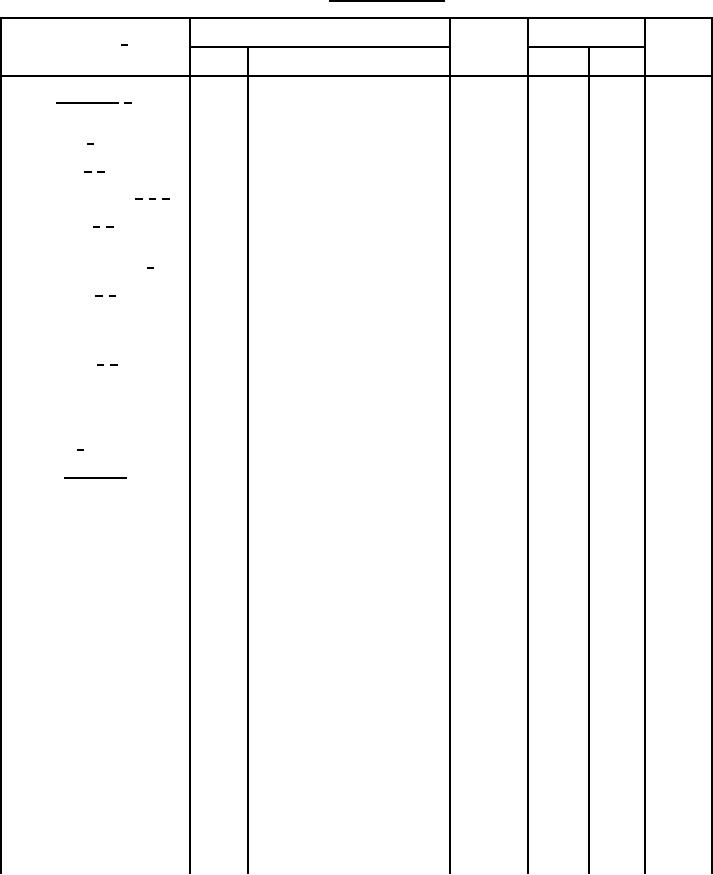

* TABLE I. Group A inspection.

Inspection 1/

MIL-STD-750

Limit

Unit

Symbol

Method

Conditions

Min

Max

Subgroup 1 2/

2071

n = 45 devices, c = 0

Visual and mechanical

examination 3/

2026

n = 15 leads, c = 0

Solderability 3/ 4/

Resistance to solvents 3/ 4/ 5/

1022

n = 15 devices, c = 0

Temp cycling 3/ 4/

1051

Test condition C, 25 cycles.

n = 22 devices, c = 0

Electrical measurements 4/

Table I, subgroup 2

Hermetic seal 4/ 6/

1071

n = 22 devices, c = 0

Fine leak

Gross leak

Bond strength 3/ 4/

2037

Precondition

TA = +250°C at t = 24 hours or

TA = +300°C at t = 2 hours

n = 11 wires, c = 0

Decap internal visual (design

2075

n = 4 devices, c = 0v

verification) 4/

Subgroup 2

°C/W

Thermal impedance

3131

See 4.3.3

ZθJX

40

V dc

Breakdown voltage

3001

Bias condition D;

V(BR)CBO

IC = 1.0 µA dc

collector to base

5.0

V dc

Breakdown to voltage

3026

Bias condition D;

V(BR)EBO

IE = 10 µA dc

emitter to base

15

V dc

Breakdown voltage,

3011

V(BR)CEO

Bias condition D; IC = 10 mA dc;

collector to emitter

pulsed (see 4.5.1)

20

V dc

Breakdown voltage,

3011

Bias condition B; IC = 10 mA dc;

V(BR)CER

collector to emitter

RBE ≤ 10 ohms; pulsed (see 4.5.1)

25

nA dc

3036

Bias condition D;

Collector to base cutoff current

ICBO1

VCB = 20 V dc

80

nA dc

Emitter to base cutoff current

3061

Bias condition D;

IEBO

VEB = 4 V dc

Forward-current

3076

15

VCE = 1 V dc;

hFE1

transfer ratio

IC = 0.5 mA dc

Forward-current

40

120

3076

hFE2

VCE = 1 V dc; IC = 10 mA dc;

transfer ratio

pulsed (see 4.5.1)

See footnotes at end of table.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business