MIL-PRF-19500/558J

4.2 Qualification inspection. Qualification inspection shall be in accordance with MIL-PRF-19500 and as

specified herein.

4.2.1 Group E qualification. Group E inspection shall be performed for qualification or re-qualification only. In

case qualification was awarded to a prior revision of the specification sheet that did not request the performance of

table III tests, the tests specified in table III herein that were not performed in the prior revision shall be performed on

the first inspection lot of this revision to maintain qualification.

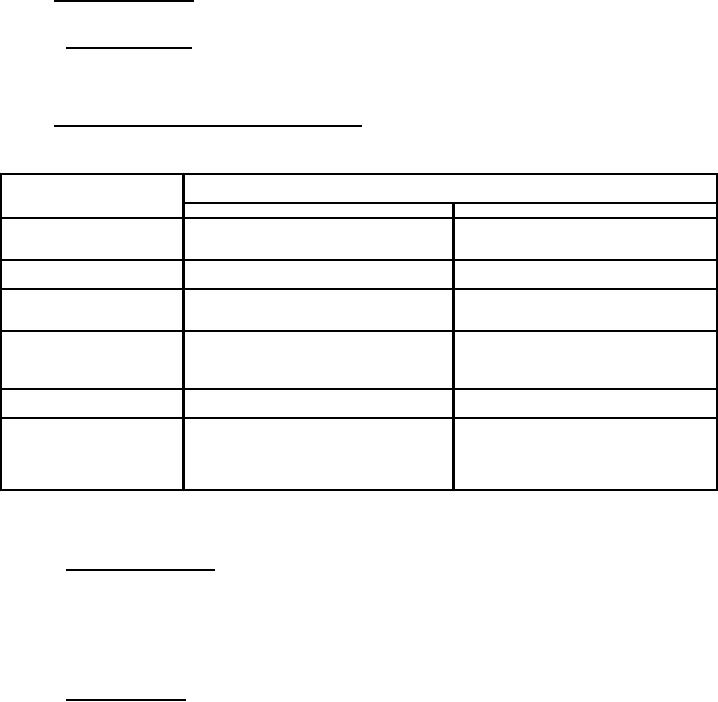

* 4.3 Screening (JANS, JANTX and JANTXV levels only). Screening shall be in accordance with table E-IV of

MIL-PRF-19500 appendix E, and as specified herein. The following measurements shall be made in accordance with

table I herein. Devices that exceed the limits of table I herein shall not be acceptable.

Screen (see appendix E, table

Measurements

E-IV of MIL-PRF-19500)

JANS level

JANTX and JANTXV levels

(1) 3c

Thermal impedance, method 3131 of

Thermal impedance, method 3131 of

MIL-STD-750, see 4.3.2.

MIL-STD-750, see 4.3.2.

9

ICBO2 and hFE4

Not applicable.

10

24 hours minimum.

24 hours minimum.

11

ICBO2 and hFE4

ICBO2 and hFE4

ĆICBO2 = 100 percent of initial value or 5 nA dc,

whichever is greater;

ĆhFE4 = ±15 percent of initial value.

12

See 4.3.1.

See 4.3.1.

13

Subgroups 2 and 3 of table I herein;

Subgroup 2 of table I herein;

ĆICBO2 = 100 percent of initial value or 5 nA dc,

ĆICBO2 = 100 percent of initial value or

whichever is greater;

5 nA dc, whichever is greater;

ĆhFE4 = ±15 percent of initial value.

ĆhFE4 = ±15 percent of initial value.

(1) Shall be performed anytime after temperature cycling, screen 3a; TX and TXV do not need to be repeated in

screening requirements.

4.3.1 Power burn-in conditions. Power burn-in conditions are as follows: VCB = 10 - 30 V dc; PT = 1.5 W for

2N6987; PT = 1.0 W for 2N6987U, and PT = 1.0 W for 2N6988. TA ambient rated as defined in 1.3. NOTE: No heat

sink or forced air-cooling on the devices shall be permitted. Power ratings apply to total package. With approval of

the qualifying activity and preparing activity, alternate burn-in criteria (hours, bias conditions, TJ, and mounting

conditions) may be used for JANTX and JANTXV quality levels. A justification demonstrating equivalence is required.

In addition, the manufacturing site's burn-in data and performance history will be essential criteria for burn-in

modification approval.

4.3.2 Thermal impedance. The thermal impedance measurements shall be performed on each die in accordance

with method 3131 of MIL-STD-750 using the guidelines in that method for determining IM, IH, tH, tMD (and VC where

appropriate). The thermal impedance limit shall comply with the thermal impedance graph on figures 9, 10, 11, and

12 (less than or equal to the curve value at the same tH time) and shall be less than the process determined statistical

maximum limit as outlined in method 3131. See table II, subgroup 4 herein.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business