MIL-PRF-19500/580C

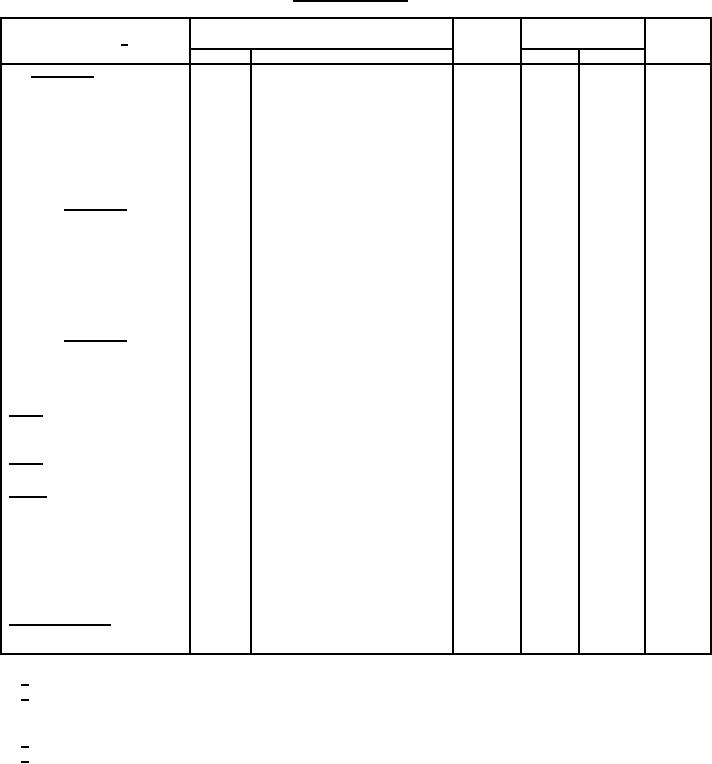

* TABLE I. Group A inspection - Continued.

Inspection 1/

Symbol

Limits

Unit

Method

Conditions

Min

Max

Subgroup 3 - Continued

TA = -55°C

Low-temperature

operation:

Forward current transfer ratio

3076

15

IC = -250 mA dc VCE = -1.0 V dc;

hFE4

pulsed (see 4.5.1),

Subgroup 4

|hFE |

3306

3

Magnitude of small-signal short-

IC = -100 mA dc, VCE = -10 V dc,

circuit forward-current transfer

f = 1 MHz

ratio

Open circuit output capacitance

3236

Cobo

100

pF

IE = 0, VCB = -10 V dc,

f = 100 KHz

Subgroup 5

TC = +25°C; t ≥ 0.5 s, 1 cycle.

3051

Safe operating area (continuous

dc)

Test 1

IC = -1.0 A dc, VCE = -6 V dc,

Test 2

IC = -500 mA dc, VCE = -12 V dc,

Test 3

2N4234

IC = -166 mA dc, VCE = -30 V dc

2N4235

IC = -100 mA dc, VCE = -50 V dc

2N4236

IC = -71 mA dc, VCE = -70 V dc

End point electricals

See 4.5.4, steps 1 and 2

Subgroups 6 and 7

Not applicable

1/ For sampling plan, see MIL-PRF-19500.

2/ For resubmission of failed subgroup 1 of table I, double the sample size of the failed test or sequence of

tests. A failure in table I, subgroup 1 shall not require retest of the entire subgroup. Only the failed test shall

be rerun upon submission.

3/ Separate samples may be used.

4/ Not required for laser marked devices.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business