MIL-PRF-19500/628C

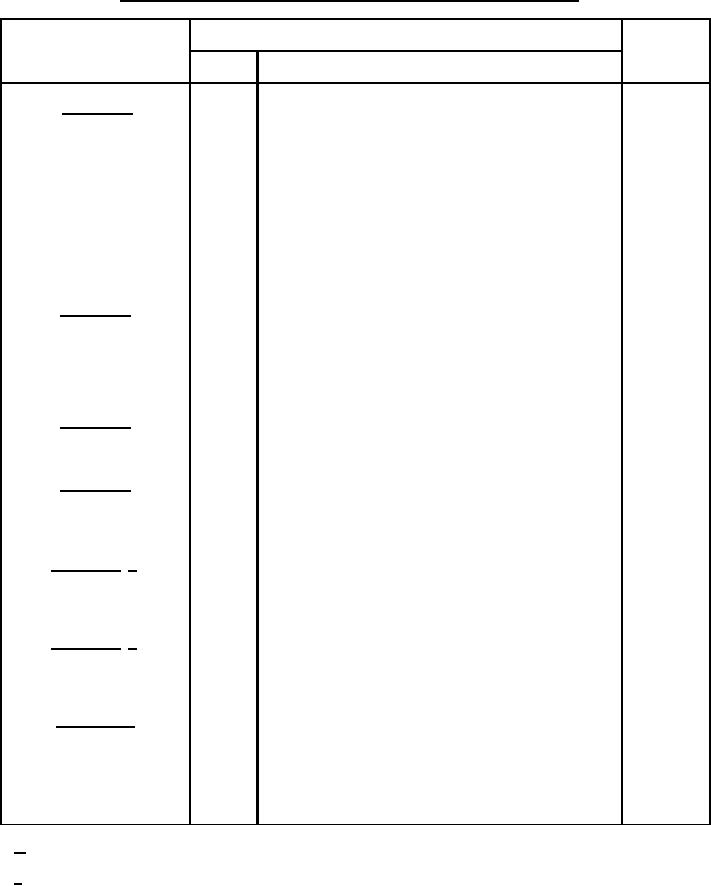

TABLE II. Group E inspection (all quality levels) for qualification and requalification only.

Inspection

Sampling

plan

Method

Conditions

Subgroup 1

45 devices

c=0

Thermal shock

1056

20 cycles, condition D except low temperature shall be

achieved using liquid nitrogen (-195°C). Visual for cracked

(glass strain)

glass.

500 cycles, -65°C to +175°C.

Temperature cycling

1051

Hermetic seal

1071

gross leak

Electrical measurement

Subgroup 2

22 devices

c=0

TA = +150°C; t = 1,000 hours +65, -0 hours; dc = 80 - 85

Blocking life

1048

percent rated VR.

Electrical measurement

See table I, subgroup 2.

Subgroup 4

Thermal impedance curves

See MIL-PRF-19500.

Subgroup 5

Insulation resistance

1016

5 devices

= 1 minute (minimum), RISO = 2.0 x 106 Ω maximum.

c=0

Subgroup 8 1/

n = 45

4065

Peak reverse power (PRM ) = shall be characterized by the

Peak reverse power

supplier and this data shall be available to the

Government. Test shall be performed on each sublot.

Subgroup 9 2/

n = 45

Resistance to glass cracking

1057

Test condition B. Step stress to destruction by increasing

cycles or up to a maximum of 25 cycles.

Subgroup 10

22 devices

c=0

Forward surge

4066

of 8.3 ms each at 1 minute intervals, IO = 0, VRWM = 0.

Electrical measurement

See table I, subgroup 2.

1/ The sample size for this step stress requirement shall be determined by the supplier. A statistically significant

sample size is required.

2/ Also applies US suffix versions.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business