MIL-PRF-19500/629C

* 4.4.3 Group C inspection. Group C inspection shall be conducted in accordance with the conditions specified for

subgroup testing in table VII of MIL-PRF-19500. Electrical measurements (end-points) shall be in accordance with

the applicable inspections of table I, subgroup 2 herein.

* 4.4.3.1 Group C inspection table VII of MIL-PRF-19500.

Method

Condition

Subgroup

C2

2036

Tension: Test condition A; weight = 20 pounds; t = 15 s. Lead fatigue:

Test condition E; weight 1 pounds. NOTE: Both tension and lead

fatigue are not applicable for US suffix devices.

C5

3101

See 4.4.5 herein.

TA = 90°C; VRWM = 40 V(pk); IO = 0, half sine wave, f = 60 Hz. TA

C6

1026

adjusted to achieve TJ = +110°C minimum.

* 4.4.4 Group E inspection. Group E inspection shall be conducted in accordance with MIL-PRF-19500 and the

conditions for subgroup testing herein. Electrical measurements (end-points) shall be in accordance with table I,

subgroup 2 herein.

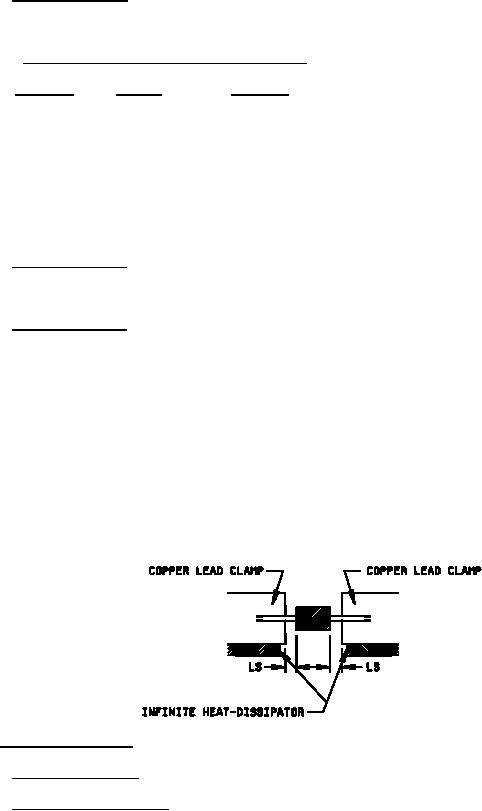

* 4.4.5 Thermal resistance. Thermal resistance measurement shall be in accordance with method 3101 or 4081 of

MIL-STD-750. Forced moving air or draft shall not be permitted across the device during test. The maximum limit for

RθJL under these test conditions shall be RθJL (max) = 20°C/W, RθJEC (max) = 10°C/W. The following conditions shall

apply when using method 3101:

a. IM ................... 1 mA to 10 mA.

b. IH .................... 3.0 A.

c. tH ................... 20 seconds minimum.

d. tMD ................. 100 µs maximum.

LS = lead spacing = .375 inch (9.53 mm) for non-surface mount devices and 0 inch for surface mount devices as

follows:

4.5 Methods of inspection. Methods of inspection shall be as specified in the appropriate tables and as follows.

4.5.1 Pulse measurements. Conditions for pulse measurement shall be as specified in MIL-STD-750.

4.5.2 Steady-state operation life. This test shall be conducted with a half-sine wave of the specified peak voltage

impressed across the diode in the reverse direction followed by a half-sine waveform of the specified average

rectified current. The forward conduction angle of the rectified current shall not be greater than 180 degrees nor less

than 150 degrees.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business