MIL-PRF-19500/349J

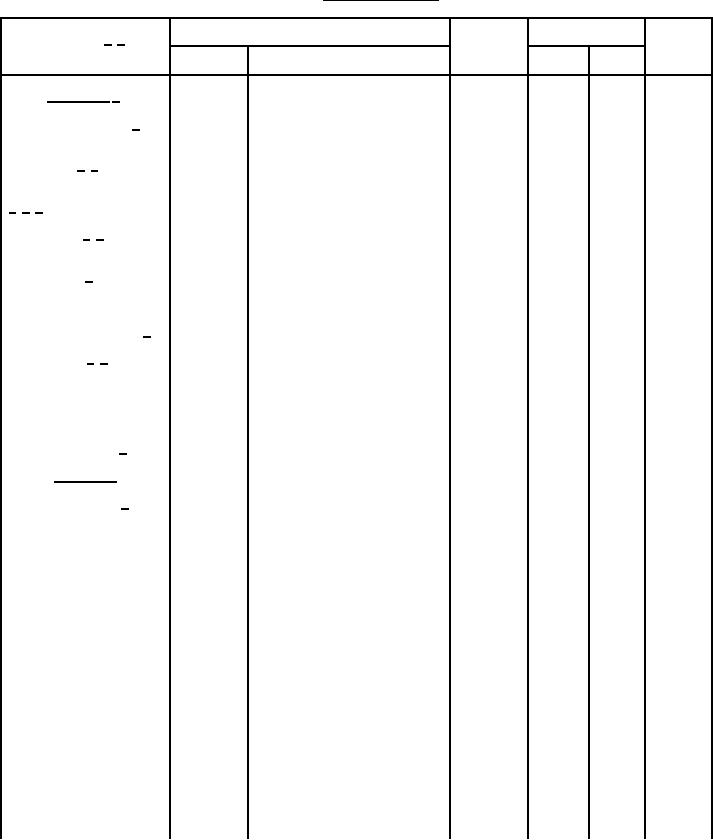

TABLE I. Group A inspection.

Inspection 1/ 2/

MIL-STD-750

Limit

Unit

Symbol

Method

Conditions

Min

Max

Subgroup 1 3/

Visual and mechanical 4/

2071

JAN, JANTX: n = 45 devices, c = 0

examination

JANTXV: n = devices, c = 0

n = 15 leads, c = 0

Solderability 4/ 5/

2026

n = 15 devices, c = 0

1022

Resistance to solvents

4/ 5/ 6/

Temp cycling 4/ 5/

1051

Test condition C, 25 cycles.

n = 22 devices, c = 0

Hermetic seal 5/

1071

n = 22 devices, c = 0

Fine leak

Gross leak

Table I, subgroup 2

Electrical measurements 5/

Precondition TA = +250°C at

Bond strength 4/ 5/

2037

t = 24 hrs or

TA = 300°C at t = 2 hrs

n = 11 wires, c = 0

Decap internal visual

2075

n = 4 devices, c = 0

(design verification) 4/

Subgroup 2

°C/W

Thermal impedance 7/

3131

See 4.3.2

ZθJX

Bias condition D, IC = 100 µA dc

Breakdown voltage collector

3001

V(BR)CBO

to base

2N3506

60

V dc

2N3507

80

V dc

Bias condition D, IE = 10 µA dc

Breakdown voltage emitter

3026

5

V dc

V(BR)EBO

to base

Breakdown voltage collector

3011

Bias condition D, IC = 10 mA dc,

V(BR)CEO

to emitter

pulsed (see 4.5.1)

2N3506

40

V dc

2N3507

50

V dc

µA dc

Collector to emitter cutoff

3041

1

Bias condition A, VEB = 4 V dc

ICEX1

current

2N3506

VCE = 40 V dc

2N3507

VCE = 60 V dc

Forward-current transfer

3076

VCE = 1 V dc, IC = 500 mA dc,

hFE1

ratio

pulsed (see 4.5.1)

2N3506

50

250

2N3507

35

175

See footnotes at the end of table

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business