MIL-PRF-19500/402F

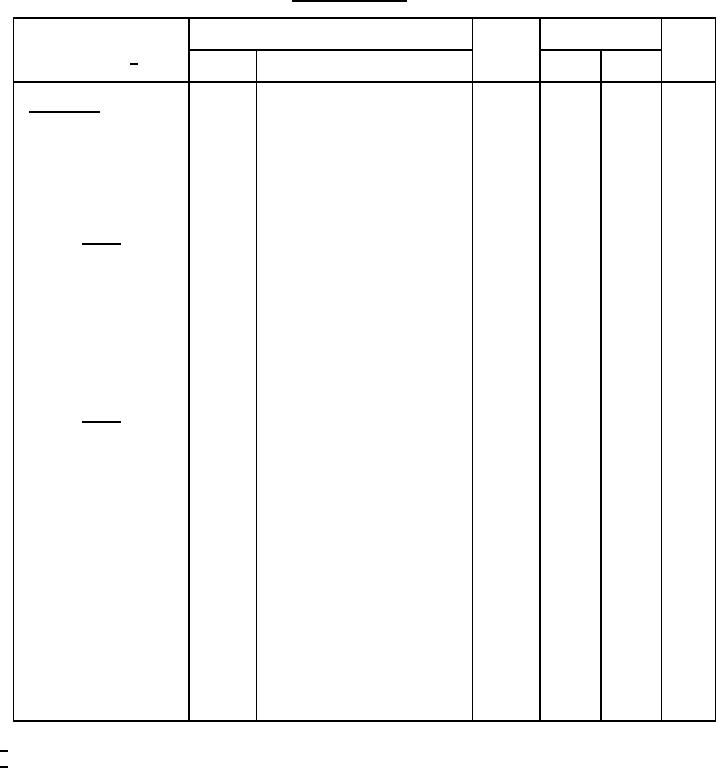

* TABLE I. Group A inspection - Continued.

Limits

MIL-STD-750

Unit

Symbol

Inspection 1/

Method

Conditions

Min

Max

Subgroup 5 - Continued

Load condition C (unclamped

3053

Safe operating area

inductive load) (see figure 5)

(switching)

TA = +25C; duty cycle 10

percent; Rs = 1; tr = tf 500 ns

Test 1

tp approx 8 ms (vary to obtain IC);

RBB1 = 100; VBB1 10 V dc;

RBB2 = ; VBB2 = 0 V dc; VCC

100 V dc; IC = 500 mA dc; the

coil used shall provide a

minimum inductance of 3.5 mH

at 500 mA with max. dc

resistance of 0.5 ohm (for

reference only: Acme T58220,

or equivalent)

Test 2

tp approx 8 ms (vary to obtain IC);

RBB1 = 100; VBB1 10 V dc;

RBB2 = ; VBB2 = 0 V dc; VCC

100 V dc; IC = 100 mA dc; the

coil used shall provide a

minimum inductance of 25 mH at

100 mA with max. dc resistance

of 1.0 ohm (for reference only:

Triad C-48u, centertapped, or

equivalent.)

TA = +25C; duty cycle 10

Safe operating area

(switching)

percent; tp approx 8 ms (vary to

obtain IC); VCC 100 V dc; IC = 1

A dc; Rs = 1; clamp voltage =

300 V dc (see figure 6)

See table I, subgroup 2

Electrical measurements

1/ For sampling plan, see MIL-PRF-19500.

2/ This test required for the following end-point measurements only:

Group B, subgroups 3, 4, and 5 (JANS).

Group B, subgroups 2 and 3 (JAN, JANTX, and JANTXV).

Group C, subgroup 2 and 6.

Group E, subgroup 1.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business