MILŁPRFŁ19500/523D

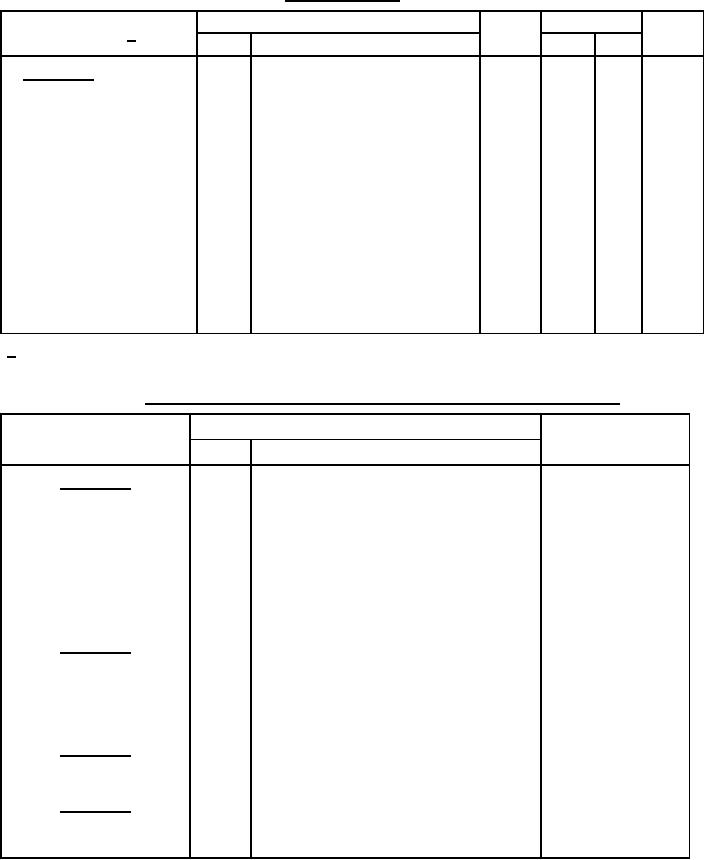

TABLE I. Group A inspection Ł Continued.

Symbol

Limit

Inspection 1/

Unit

Method

Conditions

Min

Max

Subgroup 5 Ł Continued.

Safe operating area

3053

Load condition B (clamped

(switching)

inductive load) see figure 5

TA = +25░C, tr + tf ≤ 1.0 Ąs,

duty cycle ≤ 10 percent; tp = 5 ms

(vary to obtain IC) Rs = 0.1 Ω;

VCC = 10 V dc; IC = 10 A dc

2N6383

Clamp voltage = 40 V dc

2N6384

Clamp voltage = 60 V dc

2N6385

Clamp voltage = 80 V dc

Device fails if clamp voltage is not

reached

Electrical measurements

See of table I, subgroup 2 herein

1/

For sampling plan see MILŁPRFŁ19500.

TABLE II. Group E inspection (all quality levels) Ł for qualification and re-qualification only.

Inspection

Sample plan

Method

Conditions

45 devices; c = 0

Subgroup 1

Temperature cycling

1051

Test condition G, 500 cycles.

(air to air)

Hermetic seal

1071

Fine leak

Gross leak

Electrical measurements

See of table I, subgroup 2 herein.

Subgroup 2

45 devices; c = 0

Test temperature = +125░C; VCB = 80 percent

Blocking life

1048

of rated voltage; T = 1,000 hours.

Electrical measurements

See of table I, subgroup 2 herein.

Subgroup 4

Sample size N/A

Thermal impedance curves

See MILŁPRFŁ19500.

Subgroup 8

45 devices; c = 0

Reverse voltage leakage

1033

Condition A.

stability

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business