MIL-PRF-19500/355R

4.4.5 Group E inspection. Group E inspection shall be conducted in accordance with the conditions specified for

subgroup testing in table E-IX of MIL-PRF-19500 and as specified in table III herein. Electrical measurements (end-

points) shall be in accordance with table I, subgroup 2 herein; delta measurements shall be in accordance with the

applicable steps of 4.5.8.

4.5 Methods of inspection. Methods of inspection shall be as specified in the appropriate tables and as follows.

4.5.1 Pulse measurements. Conditions for pulse measurement shall be as specified in section 4 of

MIL-STD-750.

4.5.2 Testing of units. All specified electrical tests, including end-point tests, shall be performed equally on both

sections of the transistor types covered herein, except where the electrical characteristic being evaluated applies to

the transistor as a device entity.

4.5.3 Disposition of leads when testing characteristics of each section. During the measurement of the

characteristics of each section, the leads of the section not under test shall be open-circuited.

4.5.4 Forward-current-gain ratio. The value for the forward-current-gain ratio for each individual section of a dual

unit shall be measured using method 3076 of MIL-STD-750. The forward-current-gain ratio shall be calculated by

dividing one of the values by the other. If possible, this ratio shall be measured directly to improve accuracy.

4.5.5 Base-emitter-voltage differential. The base-emitter-voltage differential shall be determined by connecting

the emitters of the individual sections together, applying specified electrical test conditions to each individual section

in accordance with method 3066 of MIL-STD-750, test condition B, and measuring the absolute value of the voltage

between the bases of the individual sections of a dual unit.

4.5.6 Base-emitter-voltage differential change with temperature. The value of the base-emitter-voltage differential

shall be measured at the two specified temperatures in accordance with 4.5.5 except that the polarities of the

differentials and identities of the individual sections shall be maintained. The absolute value of the algebraic

difference between the values at the two temperature extremes shall be calculated. A mathematical formula for this

parameter is:

|(VBE1 (T1) - VBE2 (T1)) - (VBE1 (T2) - VBE2 (T2)) |

4.5.7 Noise figure test. Noise figure shall be measured using Quan Tech Laboratories test set model no.

2173C/2181, or equivalent. Conditions shall be as specified in table I.

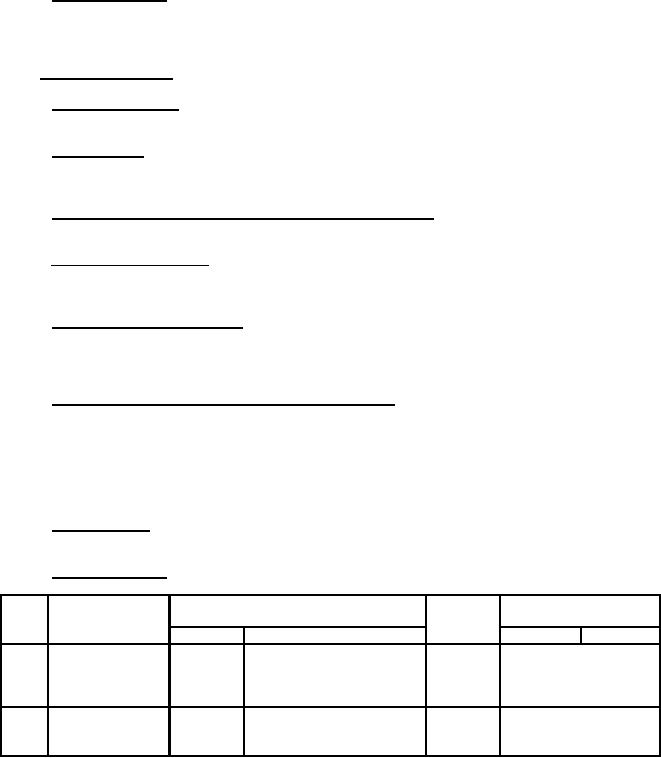

4.5.8 Delta requirements. Delta requirements shall be as specified below:

Step

Inspection

MIL-STD-750

Symbol

Limit

Method

Conditions

Min

Max

ĆICBO2

1

Collector-base

3036

Bias condition D,

100 percent of initial

cutoff current

value or 1 nA dc,

VCB = 45 V dc

whichever is greater.

±25 percent change

ĆhFE3

2

Forward current

3076

VCE = 5 V dc; IC = 1 mA dc;

transfer ratio

from initial reading.

pulsed, see 4.5.1

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business