MIL-PRF-19500/159P

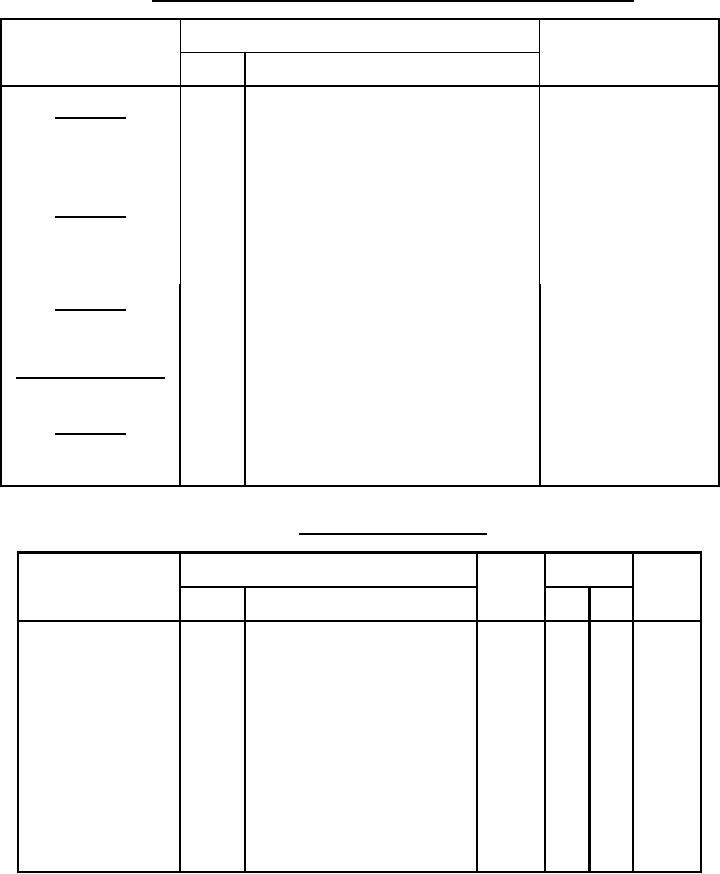

TABLE III. Group E inspection qualification and requalification (all product assurance levels).

Qualification conformance

MIL-STD-750

Inspection

inspection (sampling plan)

Method

Conditions

Subgroup 1

22 devices, c = 0

Temperature cycling

1051

500 cycles.

Electrical measurements

See table I, subgroup 2 herein.

22 devices, c = 0

Subgroup 2

Steady state operation life

1038

Condition B, 1,000 hours. (see 4.3.1).

Electrical measurements

See table I, subgroup 2 herein.

Subgroup 3

3 devices, c = 0

Decap analysis

2101

Cross section and scribe and break.

Separate samples shall be used for each test.

Subgroups 4, 5, 6, and 7

Not applicable

Subgroup 8

Step stress to destruction by increasing cycles

Resistance to glass

1057

45 devices

or up to a maximum of 25 cycles.

cracking

TABLE IV. Reference voltage time stability.

MIL-STD-750

Limits

Inspection

Symbol

Unit

Method

Conditions

Min

Max

TA = +100C 2C, IZ = 7.5 0.01

VZ

Reference-voltage time

stability

mA dc, (see 4.5.2 and 4.5.3)

mV dc

0 to 340 hours

7

1N821-1, 1N821UR-1

mV dc

7

1N823-1, 1N823UR-1

mV dc

7

1N825-1, 1N825UR-1

mV dc

6

1N827-1, 1N827UR-1

mV dc

5

1N829-1, 1N829UR-1

1N821-1, 1N821UR-1

340 to 1,000 hours

4

mV dc

1N823-1, 1N823UR-1

4

mV dc

1N825-1, 1N825UR-1

4

mV dc

1N827-1, 1N827UR-1

3

mV dc

1N829-1, 1N829UR-1

3

mV dc

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business