MIL-PRF-19500/356L

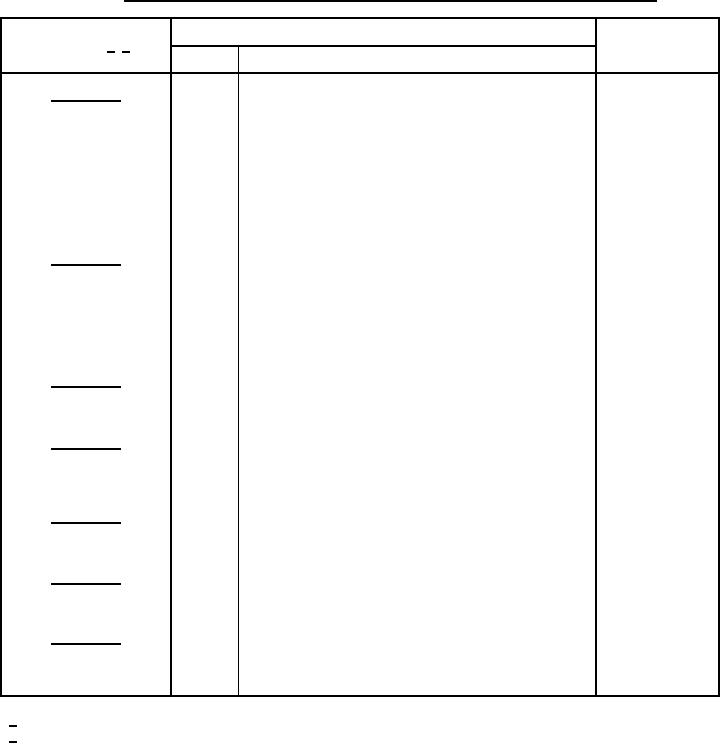

TABLE II. Group E inspection (all quality levels except die) - for qualification and requalification only.

MIL-STD-750

Inspection 1/ 2/

Sample plan

Method

Conditions

Subgroup 1

22 devices, c = 0

Thermal shock

1056

20 cycles, condition D except low temperature shall be

achieved using liquid nitrogen (-195°C). Perform a

visual inspection for cracked glass.

-65°C to +175°C, 500 cycles.

Temp cycling

1051

Hermetic seal

1071

Electrical measurements

See table III, steps 1, 2, 3, 4, 5, 6, and 7.

Subgroup 2

22 devices, c = 0

Intermittent operation life

1037

+95°C minimum, L = .375 inch (9.53 mm),

ton = toff = 3 minutes minimum for 10,000 cycles. No

heat sink or forced air cooling on the devices shall be

permitted.

Electrical measurements

See table III, steps 1, 2, 3, 4, 5, 6, and 7.

Subgroup 4

N/A

See MIL-PRF-19500.

Thermal impedance

curves

Subgroup 5

22 devices, c = 0

Barometric pressure

1001

VR = column 11 of table IV herein, (1N4990 - 1N4996

(reduced)

only) pressure = 8 mm Hg.

Subgroup 6

Not applicable

Subgroup 8

Not applicable

Subgroup 9

n = 45

Resistance to glass

1057

Condition B. Step stress to destruction by increased

cracking

cycles or up to a maximum of 25 cycles.

1/ Unless otherwise specified, for sampling plan, see MIL-PRF-19500.

2/ A separate sample may be pulled for each test.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business