MIL�PRF�19500/504F

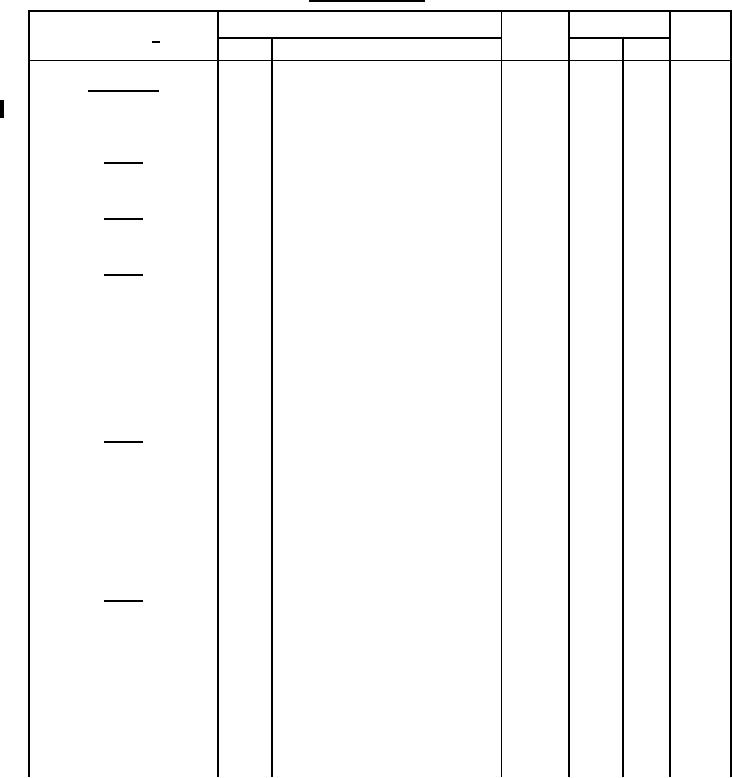

TABLE I. Group A inspection � Continued.

Limit

Inspection 1/

Symbol

Unit

Method

Conditions

Min

Max

Subgroup 5

TC = +25�C +10�C, �0�;

Safe operating area

3051

(continuous dc)

t = 1 s; 1 cycle; (see figure 3)

Test 1

(Both device types)

VCE = 8.75 V dc; IC = 20 A dc

Test 2

(Both device types)

VCE = 30 V dc; IC = 5.8 A dc

Test 3

2N6283

VCE = 80 V dc; IC = 100 mA dc

2N6284

VCE = 100 V dc; IC = 100 mA dc

Safe operating area

3053

Load condition C, (unclamped

(switching)

inductive load ); (see figure 4);

TA = +25�C; Rs ≤ 0.1 Ω;

tr + tf ≤ 15 ns;

duty cycle ≤ 2 percent;

tp = 80 �s; (vary to obtain IC);

Test 1

RBB1 ≥ 50 Ω; VBB1 ≥ 10 V dc;

RBB2 = ∞; VBB2 = 0;

IC = 20 A dc; VCC ≥ 50 V dc;

The coil used shall provide a

minimum inductance of 1 mH at 20

A. (For reference only, two coils in

parallel (Super Electric Corporation

type S16884 or equivalent).)

Test 2

= 1 ms; (vary to obtain IC);

p

RBB1 ≥ 50 Ω; VBB1 ≥ 10 V dc;

RBB2 = ∞; VBB2 = 0;

IC = 500 mA dc; VCC ≥ 50 V dc;

The coil used shall provide a

minimum inductance of 100 mH at

500 mA. (For reference only, two

coils in series, 80 mH and 20 mH

windings. Reference coils, Super

Electric Corporation type S16884 or

equivalent).

See footnotes at end of table.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business