MIL-PRF-19500/604B

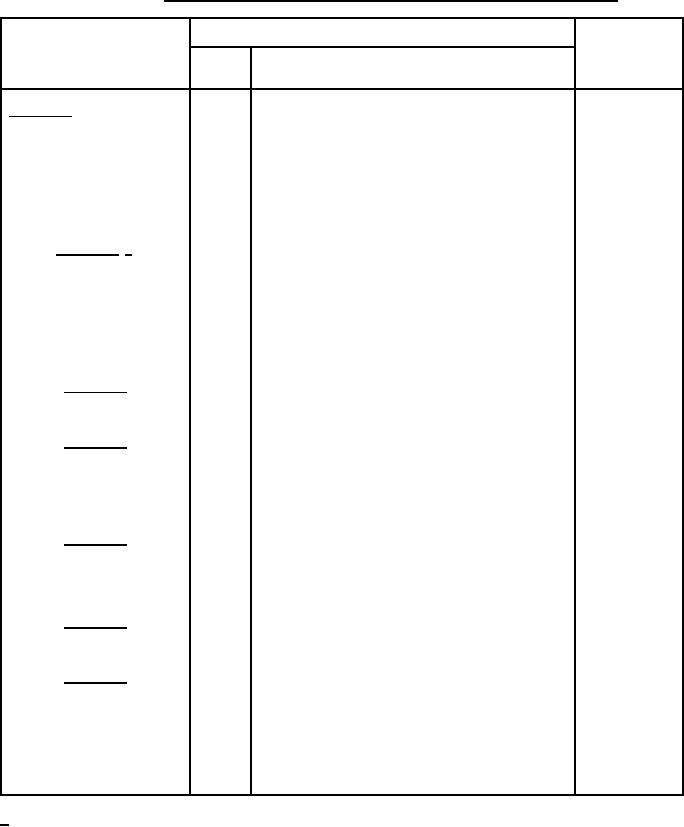

* TABLE III. Group E inspection (all quality levels) for qualification or re-qualification only.

Inspection

MIL-STD-750

Qualification and

large lot quality

Method

Conditions

conformance

inspection

Subgroup 1

12 devices

c=0

-55°C to +150°C, 500 cycles

Temperature cycling

1051

Hermetic seal

1071

Fine leak

Test conditions G or H

Gross leak

Test conditions C or D

Electrical measurements

Table I, subgroup 2 herein.

Subgroup 2 1/

12 devices

c=0

Steady-state reverse bias

1042

Condition A, 1,000 hours.

Electrical measurements

Table I, subgroup 2 herein.

Steady-state gate bias

1042

Condition B, 1,000 hours.

Electrical measurements

Table I, subgroup 2 herein.

Subgroup 3

3 devices

c=0

DPA

2102

Subgroup 4

Sample size

N/A

Thermal impedance curves

Each supplier shall submit their qual-lot average and

design maximum thermal impedance curves. In addition,

the optimal test conditions and ZθJX limit shall be provided

to the qualifying activity in the qualification report

Subgroup 5

15 devices

c=0

Barometric pressure

1001

2N7278

2N7281

Subgroup 6

3 devices

ESD

1020

Not required for devices classified as ESD class 1.

Subgroup 8

22 devices

c=0

Commutating diode for safe

3476

Test conditions shall be derived by the manufacturer

operating area test procedure

for measuring dv/dt during

reverse recovery of power

MOSFET transistors or

insulated gate bipolar transistors

1/ A separate sample for each test shall be pulled.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business