MILŁPRFŁ19500/598C

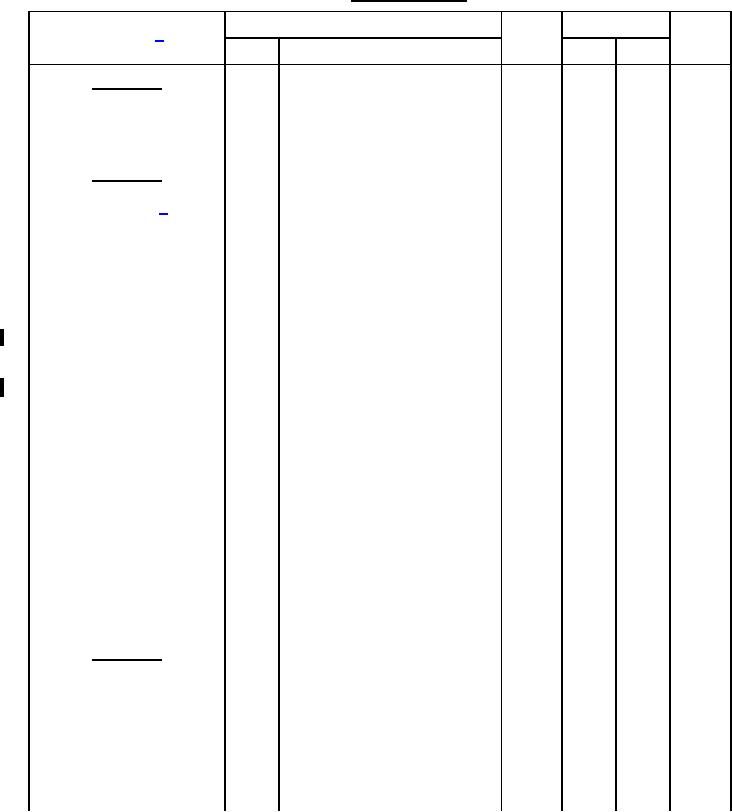

TABLE I. Group A inspection.

Limit

Inspection 1/

Unit

Symbol

Max

Min

Method

Conditions

Subgroup 1

Visual and mechanical

2071

inspection

Subgroup 2

░C/W

Thermal impedance 2/

3161

See 4.3.3

ZθJC

10

Breakdown voltage,

3407

Bias condition C, VGS = 0V,

V(BR)DSS

100

V dc

drain to source

ID = 1 mA dc

VDS ≥ VGS, ID = 0.25 mA

Gate to source voltage

3403

VGS(th)1

2.0

4.0

V dc

(threshold)

Gate current (forward)

3411

Bias condition C, VGS = +20V dc,

IGSSF1

+100

nA dc

VDS = 0 V dc

Gate current (reverse)

3411

Bias condition C, VGS = - 20 V dc,

IGSSR1

Ł100

nA dc

VDS = 0 V dc

ĄA dc

Drain current

3413

Bias condition C, VGS = 0 V dc,

IDSS1

25

VDS = 80 percent of rated VDS

Static drain to source on-state

3421

VGS = 10 V dc, condition A, pulsed

rDS(on)1

resistance

Ω

N-channel

0.7

Ω

P-channel

1.4

Forward voltage

4011

VGS = 0 V dc, ID = rated ID1, pulsed

VSD

(see 4.5.1)

N-channel

1.5

V dc

P-channel

5.5

V dc

Subgroup 3

TC = TJ = +125░C

High temperature operation:

▒200

Gate current

3411

Bias condition C, VGS = +20V dc

IGSS2

nA dc

and Ł20 V dc, VDS = 0 V dc,

Drain current

3413

Bias condition C, VGS = 0 V dc,

IDSS2

0.25

mA dc

VDS = 80 percent of rated VDS

See footnote at end of table.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business