MIL-PRF-19500/411R

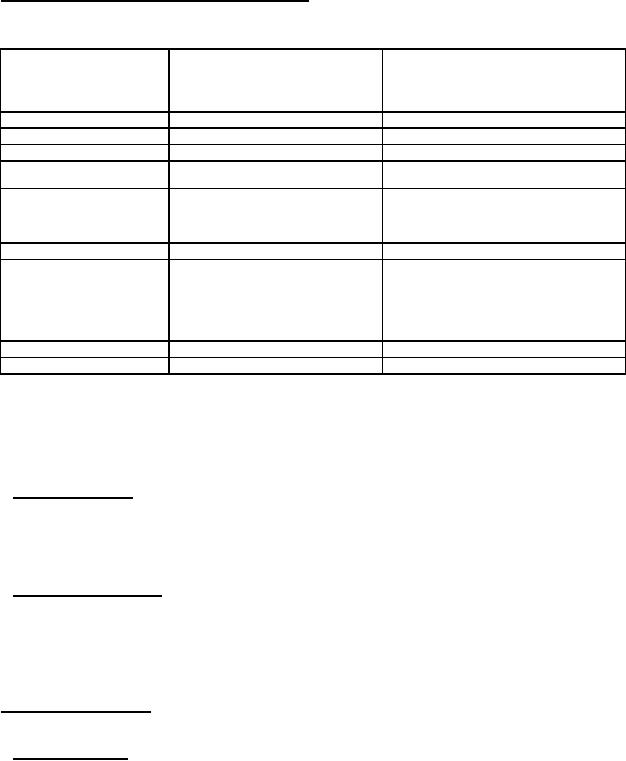

4.3 Screening (JANS, JANTXV and JANTX levels only). Screening shall be in accordance with appendix E, table

E-IV of MIL-PRF-19500 and as specified herein. Specified electrical measurements shall be made in accordance

Screening (see appendix

JANS level

JANTXV and JANTX level

E, table E-IV of

2

Optional

Not required

(1) 3c

Thermal impedance (see 4.3.1)

Thermal impedance (see 4.3.1)

IR1 and VF1

9

Not required

Method 1038 of

Method 1038 of

10

MIL-STD-750, condition A

MIL-STD-750, condition A

IR1 and VF1; ĆIR1 ≤ 100 percent

IR1 and VF1

(2) 11

of initial reading or 250 nA dc,

whichever is greater;

ĆVF1 ≤ ±0.1 V dc

12

Required, see 4.3.2

Required, see 4.3.2

Subgroups 2 and 3 of table I

(2) (3) 13

herein; ĆIR1 ≤ 100 percent of

100 percent of initial value or 250 nA

dc, whichever is greater; ĆVF1 ≤ ±0.1

initial value or 250 nA dc,

whichever is greater; ĆVF1 ≤

V dc, scope display evaluation (see

±0.1 V dc, scope display

evaluation (see 4.5.2)

15

Required

Not required

16

Required

Not required

(1) Thermal impedance shall be performed any time after sealing provided temperature cycling is performed in

accordance with MIL-PRF-19500, screen 3 prior to this thermal test.

(2) For JANTX and JANTXV devices, ΔVF1 may be omitted if thermal impedance is performed, unless irradiation is

used to reduce the carrier lifetime.

(3) ZθJX is not required in screen 13, if already previously performed.

4.3.1 Thermal impedance. The thermal impedance measurements shall be performed in accordance with method

3101 of MIL-STD-750 using the guidelines in that method for determining IM, IH, tH shall be 10 ms, tMD shall be 70 µs

maximum. The thermal impedance limit shall comply with the thermal impedance graphs herein (less than or equal

to the curve value at the same tH time) and shall be less than the process determined statistical maximum limit as

outlined in method 3101. See table III, subgroup 4 herein.

4.3.2 Power burn-in conditions. Power burn-in conditions are as follows: IO = 3A minimum; TA = 55°C maximum.

Test conditions in accordance with method 1038 of MIL-STD-750, condition B. Use method 3100 of MIL-STD-750 to

measure TJ. Adjust IO or TA to achieve the required TJ. TJ = 135°C minimum. With approval of the qualifying

activity, alternate burn-in criteria (hours, bias conditions, TJ, mounting conditions) may be used for JANTX and

JANTXV quality levels. A justification demonstrating equivalence is required. In addition, the manufacturing sites

burn-in data and performance history will be essential criteria for burn-in modification approval.

4.4 Conformance inspection. Conformance inspection shall be in accordance with MIL-PRF-19500 and as

specified herein.

4.4.1 Group A inspection. Group A inspection shall be conducted in accordance with MIL-PRF-19500, and table I

herein. The ZθJX end-point shall be derived by the supplier and approved by the qualifying activity. This ZθJX end-

point shall be documented in the qualification report.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business