MILPRF19500/427P

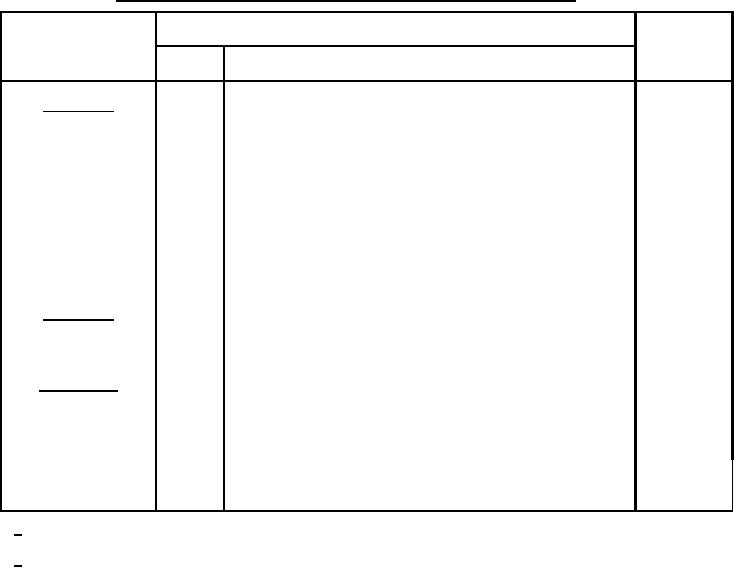

TABLE II. Group E inspection (all quality levels) for qualification and requalification only - Continued.

Inspection

Sampling

plan

Method

Conditions

Subgroup 8

Peak reverse power

4065

45 devices

Peak reverse power (PRM)= shall be characterized by the supplier

c=0

and the data shall be available to the Government. Test shall be

performed on each sublot.

Electrical

During the PRM test, the voltage (VBR) shall be monitored to verify

measurement

it has not collapsed. Any collapse in VBR during or after the PRM

test or rise in leakage current (IR) after the test that exceeds IR1 in

table I, herein shall be considered a failure to that level of applied

PRM. Progressively higher levels of PRM shall be applied until

failure occurs on all devices within the chosen sample size.

Subgroup 9

45 devices

c=0

1057

Test condition B. Step stress to destruction by increasing cycles

Resistance to glass

or up to a maximum of 25 cycles.

cracking

Subgroup 10

22 devices

c=0

Forward surge

4066

Electrical

measurement

1/

Test method 1056 of MIL-STD-750, test condition D, using liquid nitrogen, may be used in lieu of test method

1051 of MIL-STD-750.

2/

For opaque glass diodes use test method 2068 of MIL-STD-750.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business