MIL-PRF-19500/444N

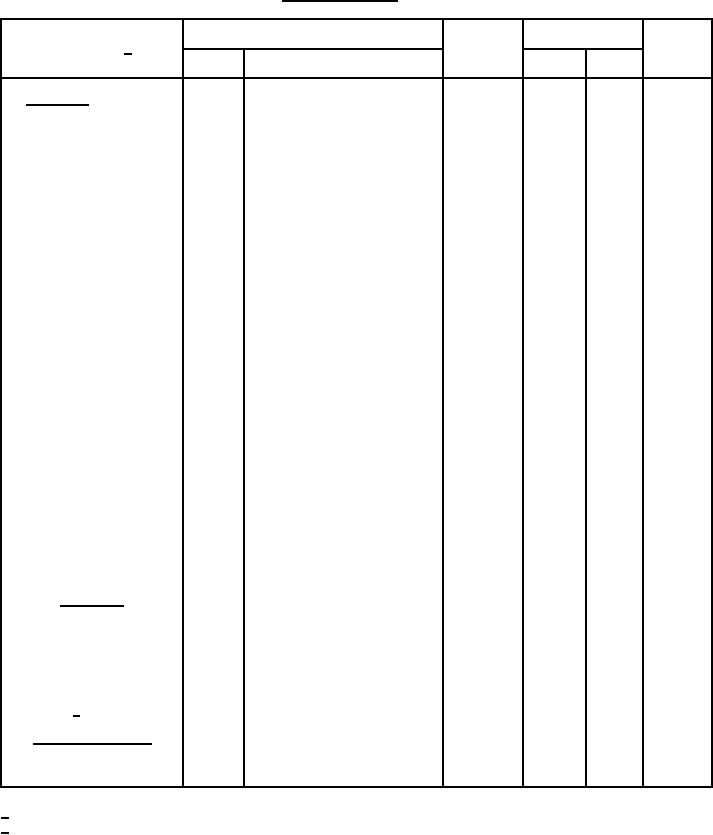

TABLE I. Group A inspection - Continued.

MIL-STD-750

Limit

Inspection

1/

Symbol

Unit

Method

Conditions

Min

Max

Subgroup 3 - Continued.

TA = +150°C

1N5712-1, all packages

High temperature operation

µA dc

Reverse current

4016

DC method; VR = 16 V dc

IR2

150

TA = -55°C

Low temperature operation

Forward voltage

4011

IF = 1 mA dc

VF3

0.55

V dc

Forward voltage

4011

IF = 35 mA dc

VF4

1.0

V dc

IR = 10 µA dc

Breakdown voltage

4021

V(BR)2

20

V dc

1N6857-1, UR-1

TA = +150°C

High temperature operation

µA dc

Reverse current

4016

DC method; VR = 16 V dc

IR2

300

TA = -55°C

Low temperature operation

Forward voltage

4011

IF = 1 mA dc

VF3

.55

V dc

Forward voltage

4011

IF = 35 mA dc

VF4

1.0

V dc

IR = 10 µA dc

Breakdown voltage

4021

V(BR)2

20

V dc

TA = +150°C

1N6858-1, UR-1

High temperature operation

µA dc

Reverse current

4016

DC method; VR = 50 V dc

IR2

400

TA = -55°C

Low temperature operation

Forward voltage

4011

IF = 1 mA dc

VF3

.55

V dc

Forward voltage

4011

IF = 15 mA dc

VF4

1.0

V dc

IR = 10 µA dc

Breakdown voltage

4021

V(BR)2

70

V dc

Subgroup 4

Capacitance

4001

C

1N5711-1, 1N5712-1, and UB

Vr = 0V dc; f = 1 MHz;

2.0

pF

and UR

1N6857-1, 1N6858-1, and UR

Vsig = 50 mV(pk) maximum

4.5

pF

τCL

Effective carrier lifetime

(See DESC drawing C68001)

100

ps

(see 4.5.2) 2/

Subgroups 5, 6, and 7

Not applicable

1/ For sampling plan, see MIL-PRF-19500.

2/ Effective carrier lifetime needs to be performed only one time for each wafer lot.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business