MIL-PRF-19500/503H

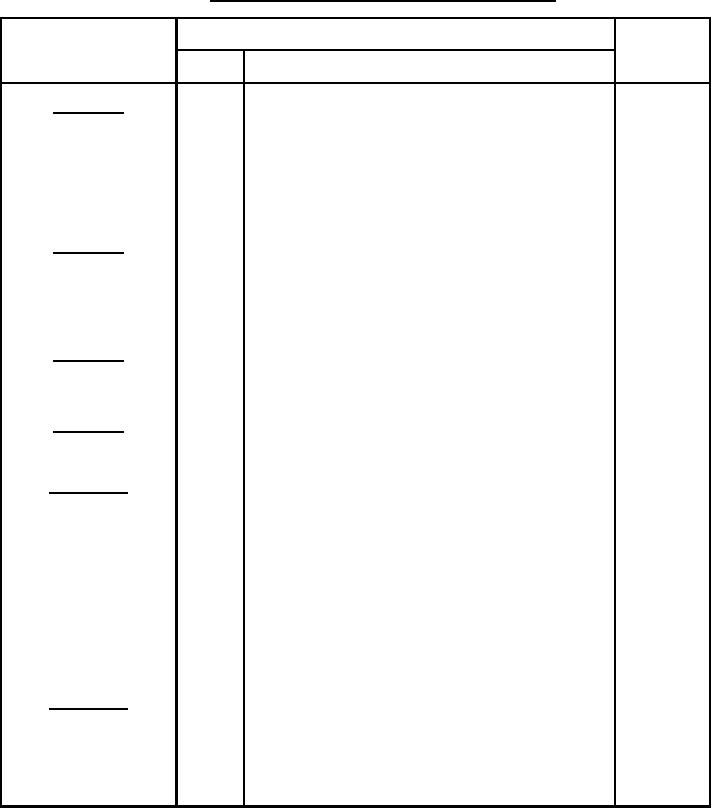

TABLE II. Group E inspection (all quality levels) for qualification only.

Inspection

Sampling

plan

Method

Conditions

Subgroup 1

45 devices

c=0

-65°C to +175°C, 500 cycles.

Temperature cycling (air

1051

to air)

Hermetic seal

1071

Electrical measurement

See table III, steps 1, 2, 3, 4, and 5.

Subgroup 2

22 devices

c=0

t = 1,000 hours; TA = +150°C; VR dc = 80 - 85 percent

Blocking life

1048

Electrical measurement

See table III, steps 1, 2, 3, 4, and 5.

Subgroup 4

N/A

Thermal impedance

See MIL-PRF-19500.

curves

Subgroup 5

Not applicable

Subgroup 10

Peak reverse power, (PRM)= shall be characterized by the

Peak reverse power

4065

supplier and this data shall be available to the Government.

Test shall be performed on each sublot.

Electrical measurement

During the PRM test, the voltage (VBR) shall be monitored to

verify it has not collapsed. Any collapse in VBR during or

after the PRM test or rise in leakage current (IR) after the

to that level of applied PRM. Progressively higher levels of

PRM shall be applied until failure occurs on all devices

within the chosen sample size to characterize each sublot.

Subgroup 11

22 devices

c=0

Forward surge

4066

each at 1 minute intervals superimposed on IO = IO1 rated

Electrical measurement

See table III, steps 1, 2, 3, 4, and 5.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business