MIL-PRF-19500/429N

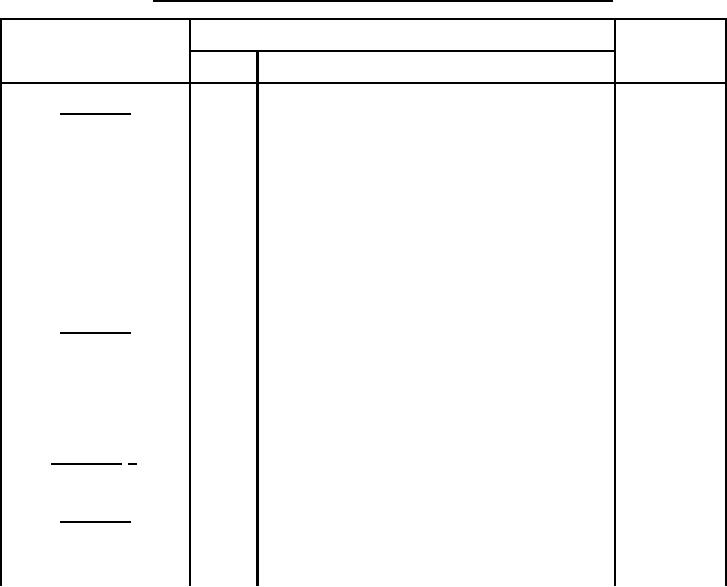

TABLE II. Group E inspection (all quality levels) for qualification and requalification only.

Inspection

Sampling plan

Method

Conditions

Subgroup 1

45 devices

c=0

Thermal shock

1056

20 cycles, condition D except low temperature shall be

achieved using liquid nitrogen (-195°C). Perform a

visual for cracked glass.

500 cycles, -65°C to +175°C.

Temperature cycling

1051

Hermetic seal

1071

Gross leak

Electrical measurements

Subgroup 2

22 devices

c=0

1,000 hours; VR = 80 85 percent of rated VRWM (see

Steady state dc blocking life

1048

col. 2 of 1.3).

Electrical measurements

See table I, subgroup 2 herein except for thermal

impedance and table III, step 1. For irradiated devices,

include trr as an end-point measurement.

Subgroup 4 1/

Thermal impedance curves

See MIL-PRF-19500.

Subgroup 5

22 devices

c=0

Barometric pressure,

1001

Pressure 1N5617, 1N5619 = 8 mm Hg (100,000 ft);

1N5621, 1N5623 = 33 mm Hg (70,000 ft); VR = VRWM

reduced (altitude operation)

(see col. 2 of 1.3); t = 1 minute (minimum).

See footnote at end of table.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business